Nov. 26, 2025

Bring Potaro to Medical Sites as Soon as Possible!Aiming for a Lean Introduction Process for In-Hospital Transport Robots

At Toyota Memorial Hospital (Toyota City, Aichi Prefecture), operated by Toyota Motor Corporation, efforts are underway to improve the quality of medical care with the goal of creating a "hospital full of smiles and sincerity." As part of this initiative, our Frontier Research Center collaborated with Toyota Memorial Hospital to reform logistics operations within the hospital in line with the opening of a new ward in May 2023. We developed the in-hospital transport robot "Potaro" and introduced 24 units*1*2*3.

- Could you tell us about Potaro developed by the Frontier Research Center, and the logistics system utilizing it?

- Taniai

- The logistics system using Potaro is based on the Toyota Production System (TPS) principle of "delivering what is needed, when it is needed, and in the amount needed." To achieve this, 24 Potaro units work together to efficiently move around the hospital. Potaro is a robot capable of autonomous movement inside the building based on pre-acquired building map data and coordinates of waypoints―pre-registered passing points. By following numerous rules such as which corridors to take, where to stop, and how to coordinate with elevators and automatic doors, Potaro performs transport tasks that were previously done by medical staff. By transforming operations with Potaro, we aim to enable medical staff to dedicate more time to care that only they can provide.

- How has the working style of medical staff changed at Toyota Memorial Hospital since introducing Potaro?

- Taniai

- After about two years of operation, we have received feedback from medical staff saying they now have time to give close attention to patients with anxiety and listen to them carefully―showing a shift toward patient-focused nursing. This is the most gratifying outcome for us. We feel we have taken the first step in the medical field toward Toyota's mission of "Producing Happiness for All."

- That's wonderful. I've heard Japanese medical sites face many challenges, such as an aging society and work style reforms for medical staff. It would be great if the changes realized at Toyota Memorial Hospital could spread to other hospitals as well.

- Taniai

- Thank you. However, while working on Potaro's introduction at Toyota Memorial Hospital, we also strongly felt there are still many challenges to overcome before this kind of in-hospital transport system can be widely adopted.

- What challenges did you face when introducing the system at Toyota Memorial Hospital?

- Taniai

- A major challenge was the time and effort required for on-site introduction of Potaro, meaning the labor involved in setting it up. The complex rule settings needed for the 24 Potaro units to coordinate their movements required a lengthy introduction period―about four months*4 at Toyota Memorial Hospital to complete the system setup. However, we cannot invest such a large amount of effort each time when expanding to many hospitals. Also, much of the setup required specialized knowledge and experience from robot development engineers, so it was not in a state where anyone could easily implement it. Transforming this introduction process into a leaner one―that is, eliminating waste and making it easy, fast, and simple for anyone to do―is our urgent task.

- I see. Even if it works at one hospital, there are hurdles to overcome to spread it further. How are you addressing these challenges?

- Taniai

-

To realize this lean introduction process, we have broken down the process into steps such as defining service specifications, system construction, and actual machine verification, and have been developing technologies to shorten the introduction period at each stage. I will share three examples regarding the system construction phase.

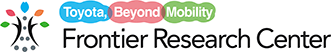

First, in the system construction phase, the initial task is map creation for robot navigation. Previously, we ran a dedicated robot inside the hospital, spending a lot of time measuring every corner. Now, we have developed a technology to automatically generate a robot map directly from the hospital's architectural blueprints. With just the blueprint data, we can quickly create a simulation map without visiting the site.

-

- Automated simulation map creation

- Taniai

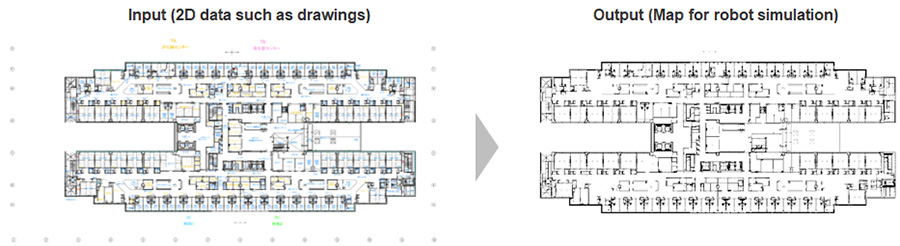

- Second, to shorten the system construction phase, we changed the system's main server from an on-premises physical terminal installed inside the hospital to a pre-built cloud environment. This significantly reduced the effort required to set up the environment. Furthermore, by coding the cloud environment's configurations, we can quickly rebuild it during development or when failures occur.

-

- Shortening the server deployment timeline

- Taniai

- Third, the most complex part of the system construction phase is rule setting efficiency. I will have Mr. Ueda, who was in charge of development, explain this.

- Could you tell us about the most complex rule setting?

- Ueda

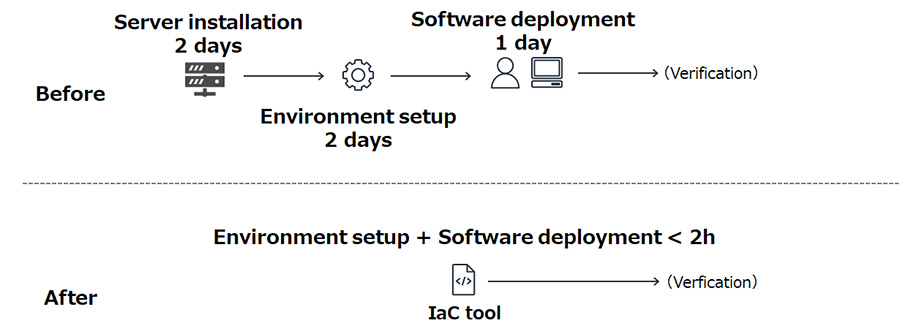

- Since many Potaro units move simultaneously, we need a traffic control mechanism to prevent robots from meeting face-to-face in narrow corridors. Specifically, the robots stop before narrow corridors where passing is not possible, obtain a right of way, and then enter. We need to set waiting spots (one type of waypoint) on the map to acquire this right of way. Previously, placing these spots was done manually one by one, which took a lot of time. So, we developed an algorithm that automatically reads corridor widths, identifies places where passing may be impossible, and places waiting spots automatically. This made setting much easier.

- Can you explain the algorithm in detail?

- Ueda

- The algorithm applies a spatial partitioning method called the extended Voronoi diagram*5. It sets a threshold distance that robots need to pass each other and draws Voronoi lines on the map. Depending on the number of lines, corridors are classified into opposing lane and mutual traffic lane routes. Waiting spots are placed at the boundaries, achieving automation.

-

- Automatic placement algorithm for waiting areas

- How did you verify the developed introduction process?

- Ueda

-

In March 2025, just before opening, we conducted the first external technical verification at Chitahanto Medical Center (Handa City, Aichi Prefecture). This was a critical step to check if the process developed to reduce introduction effort works at hospitals with different environments than Toyota Memorial Hospital.

Preparations such as scenario settings on the PC were completed within the target of a few days, thanks to the developed introduction process. However, when operating the robots on-site, unexpected issues continuously arose. The biggest challenge was coordinating with other companies' automatic doors and elevators. The robots did not work smoothly, and we had to make fixes on-site until just before the demonstration.

Through this on-site experience, we confirmed both the effectiveness of the developed introduction process and challenges that can only be identified on-site. We feel this was a definite step toward realizing a lean introduction process.

-

- Demonstration of technical verification

- Another step forward for spreading it to the world! What feedback did you receive from people at Chitahanto Medical Center?

- Taniai

- After Potaro successfully moved inside the hospital, we demonstrated the transport service to hospital staff. Participants highly praised Potaro's delivery placement function and large load capacity. On the other hand, they pointed out new challenges, such as slightly unstable movements when avoiding people, revealing new hurdles to overcome. We also received hopeful comments about a future where robots play active roles in medical fields. Being able to hear both the expectations and challenges from the field was our greatest gain. We are truly grateful to everyone at Chitahanto Medical Center who cooperated in the experiment. We will continue to take on challenges to meet everyone's expectations.

- How will the introduction process evolve going forward?

- Ueda

- For example, the automatic placement algorithm of waypoints is still not perfect. At intersections, waypoints tend to cluster, requiring manual adjustments. We want to resolve these issues one by one and aim to further reduce the introduction workload.

- Thank you very much. We look forward to Toyota's Frontier Research Center's efforts bringing happiness to more people.

- Taniai

- Thank you. Our goal at the Frontier Research Center is not simply to create convenient robots. Through the introduction of Potaro, we want to create an environment where medical staff can focus on specialized and warm care that only they can provide. Beyond that lies the happiness of each patient. We want to spread this vision of creating a workplace environment where medical professionals can focus solely on patient care first throughout Japan, and then worldwide. Since we cannot achieve this challenge alone, we will continue to accelerate research in cooperation with external researchers, medical institutions, and companies, to contribute to medical sites as soon as possible.

Authors

Osamu Taniai

Robotics Solutions Group, R-Frontier Div., Frontier Research Center

Yoshiki Ueda

Robotics Solutions Group, R-Frontier Div., Frontier Research Center

References

| *1 | Toyota's Frontier Research Center―On-Site Training for Research and Development |

|---|---|

| *2 | Robots Carrying Medicine in Place of Humans!―Assisting Hospital Robots with Over 200 Ceiling Cameras |

| *3 | Kaizen Meets Healthcare at Toyota Memorial Hospital's New Ward |

| *4 | The setup period required to introduce and operate the system on-site |

| *5 | A method of dividing regions on a plane based on distances

|

Contact Information (about this article)

- Frontier Research Center

- frc_pr@mail.toyota.co.jp