Apr. 04, 2019

Toyota Introduces Station for the Production and Supply of Hydrogen from Renewable Energy at Motomachi PlantPromoting the introduction and use of hydrogen energy-based technologies to meet the Plant Zero CO2 Emissions Challenge

Toyota City, Japan, April 4, 2019―Toyota Motor Corporation (Toyota) announces today that it has newly introduced SimpleFuel™*1 to its Motomachi Plant in Toyota City, Aichi Prefecture. SimpleFuel™ is a small water electrolysis-based machine for hydrogen generation and filling that can produce, store, and supply hydrogen by making use of electricity generated from solar power, a renewable energy resource.

SimpleFuel™ is a simplified hydrogen station that uses electricity from solar panels at the plant site to produce low-carbon hydrogen from the electrolysis of water, which is then supplied to fuel-cell forklifts (FC forklifts) after it is compressed and pressurized. It can produce up to 99 Nm3/day (approx. 8.8 kg/day) of hydrogen, enough to fuel seven or eight FC forklifts. Its compact size means it can be installed in small spaces, making it suitable for refueling FC forklifts within the plant.

A hydrogen station has been running at Motomachi Plant since March 2018, in conjunction with the increasing numbers of FC forklifts in use there. By working to support fueling through the use of SimpleFuel™, with an eye toward the rising demand for hydrogen, Toyota aims to reduce CO2 emissions at the Motomachi Plant and intends to support the accumulation of new technologies and knowledge.

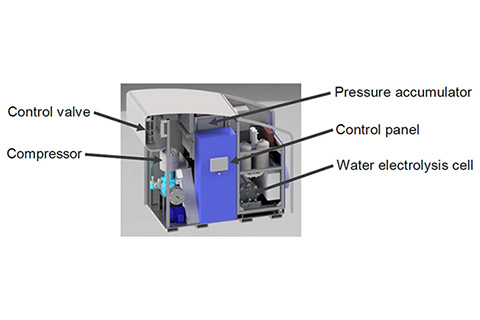

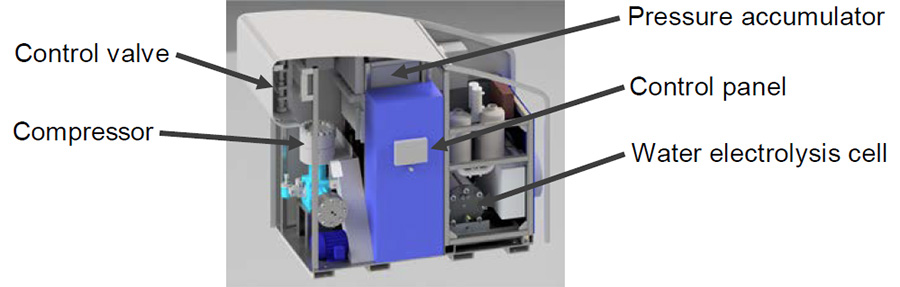

Outline of SimpleFuel™

-

- Installation

-

- Internal structure*2

Specifications*2

| Hydrogen production capacity (max.) | 99 Nm3/day (8.8 kg/day) |

|---|---|

| Storage volume | 72.18 Nm3 |

| Hydrogen purity | 99.97% |

| Hydrogen filling pressure | 35 MPa |

| Hydrogen generation method | Alkaline water electrolysis method |

To reduce CO2 emissions at its plants, Toyota intends to replace existing conventional forklifts with fuel cell forklifts. This endeavor began at Motomachi Plant, with the introduction of two Toyota Industries Corporation FC forklifts in 2017, followed by an additional twenty in 2018. This year, the Ministry of the Environment's "Subsidy for Business Costs, etc. for Measures Combating Carbon Dioxide Emissions (Project to Promote Low Carbon Social Infrastructures that Utilize Renewable Energy-based Hydrogen)" makes possible the introduction of SimpleFuel™ and an additional 50 FC forklifts.

Through the Aichi Low-Carbon Hydrogen Supply Chain Promotion Association, along with Aichi Prefecture and related local authorities and companies, Toyota is promoting the low-carbon footprint of the hydrogen supply chain as a whole through use of renewable resources and the concept of "production, transportation, and use." This plan to use hydrogen produced from electricity from renewable sources generated at Motomachi Plant has now been certified through Aichi Prefecture's Low Carbon Hydrogen Certification System.

Since launch of the Toyota Environmental Challenge 2050 in 2015, Toyota has been developing and implementing technologies by harnessing hydrogen energy, which is aimed at utilizing hydrogen at its plants to realize its Plant Zero CO2 Emissions Challenge. Toyota is steadily working on various initiatives to reach this goal, including promoting the introduction and use of SimpleFuel™ and FC forklifts at its Motomachi Plant.

| *1 | SimpleFuel™ is a product of and jointly manufactured by IVYS Energy Solutions and PDC Machines in the U.S. |

|---|---|

| *2 | Data provided by TOKYO BOEKI MECHANICS Ltd. (responsible for sales in Japan). |

"Achieving zero, and adding new value beyond it"

As part of efforts to pass our beautiful "Home Planet" to the next generation, Toyota has identified and is helping to solve issues faced by individuals and overall society, which Toyota calls "Achieving Zero," hoping to help reduce the negative impacts caused by these issues to people and the environment to zero. Additionally, Toyota is also looking "Beyond Zero" to create and provide greater value by continuing to diligently seek ways to improve lives and society for the future.

- About Beyond Zero

- https://global.toyota/en/mobility/beyond-zero/