May 15, 2019

The master craftsmanship of the Century, Japan's only chauffeur-driven car

A look inside Toyota Motor East Japan's Higashi-Fuji Plant, which is responsible for producing every Century model, reveals the many ways master craftsmen leave their mark.

A full model change in June 2018 led to the development of the third-generation Century, which remains Japan's only chauffeur-driven automobile. Each Century model has been handcrafted at Higashi-Fuji Plant of Toyota Motor East Japan, Inc. (former Kanto Auto Works, Ltd.). What are the skills required to create Century models produced at this plant?

A look back at past Century models

| 1st generation (1967-1997) | 2nd generation (1997-2017) | 3rd generation (June 2018 to date) |

|---|---|---|

| The birth of a true chauffeur-driven car | Carved out a solid position through master craftsmanship and advanced equipment. | Established its status as an ultra-luxury car through legacy and evolution. |

| V8/3L All-aluminum engine |

V12/5L Japan's first V12 engine for passenger cars |

V8/5L An environmentally friendly HEV engine |

The plant where the Century is produced is very different to a standard mass-production plant. There is no assembly line, no long row of cars. There is no sound of electronics or machinery. In this quiet, spacious area, a small number of highly trained, skilled craftsmen create cars almost as if they are producing works of art. The production process for the Century has five steps: stamping, body, painting, assembly, and inspection. Each step incorporates the master craftsmanship one would expect for a Century.

The chamfered lines of the Century

One of the focal points of the exterior design of the new Century model is the character line that runs down both flanks. This is formed using a traditional chamfering method known in Japanese as "kichomen." This term originally referred to the elaborate way the posts of kicho, Heian period (794-1185) room partitions used by nobles to provide private areas for themselves, were chamfered to avoid leaving a simple angle. The finely-detailed, intricate workmanship on these partitions has led to the adjective "kichomen" coming to mean "to carry out work accurately and carefully."

The kichomen chamfering on the Century body is created by skilled hands that create the curves when producing such angles.

-

-

- Ensuring a perfectly smooth body

-

-

-

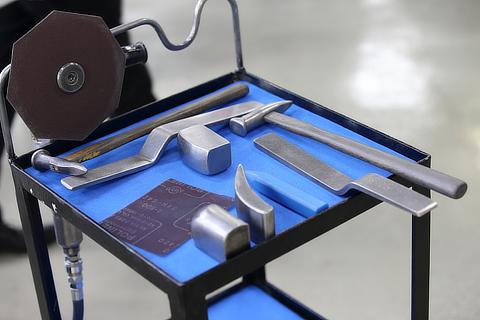

- Finishing touches with a sander

-

The minor imperfections on the body panels after processing in the press are delicately smoothed, creating a precise, unbroken line. The metal is then finished with power sanders. This is a task that demands the utmost concentration: even the motion of breathing could affect the dynamism of this line.

Deliberate misalignment is the mark of a master

To complete the body, the kichomen chamfer line must match perfectly from the front to the rear. However, as befits a luxury car, the doors on the Century are extremely thick and heavy, and so once the weight of the interior finishings is added later on, the rear ends of the doors will drop slightly from their original positions. Here, a technique known as "door-lifting" is employed. In other words, to align with the descent of the door, the alignment is deliberately adjusted to ensure that it looks perfect when the car is completed.

Finally, all body panels are checked by viewing them very closely from the side to confirm that they are all aligned precisely.

The car is a mirror reflecting tradition and its passengers

While four exterior colors are available for the new Century, black is its signature color. It is a newly-developed "eternal black" known as Kamui. This unique color, which gives the impression of black lacquer, is created through processes exclusive to the Century.

The first is the sheer number of coats. While a standard car would have four coats, the Century has seven, including a clear coating containing black pigment to create a truly rich depth to the paintwork. The second is the wet sanding process. Three times, between coats, the microscopic imperfections in the paintwork are sanded under running water, creating a smooth, even surface. Spending time to create the perfect undercoat is the key to creating a beautiful finish. Finally, a mirror-finish polish ensures that not the slightest cloudiness or dullness remains.

Additionally, before the new Century model's production begins, workers from the Higashi-Fuji Plant visit Wajima lacquerware workshops in Ishikawa Prefecture to learn the Japanese traditional craft of lacquerware production. The aim is to realize the ultimate black in lustrous finishes, in reference to the technology of lacquerware technology with a smooth and lustrous black color.

-

-

- Demonstration of mirror-finish polishing

-

-

- Tradition of master craftsmanship

Many of those who purchase a Century are VIPs. When alighting from the rear seats, the Century's body becomes almost like an elegant mirror, allowing its passengers to casually check their appearance. This mirror finish is just one of the ways the Century caters to those who are fortunate to own one.

Honed senses

Even installing the tower console located between the front seats requires delicate work by hand. The key is making sure it is precisely even between both seats. Experienced craftsmen can sense the degree of tilt to either side, and carefully turn the bolts to adjust the center console position. This is not something that can be reduced to numbers; the work is achieved through the special trust in the senses and experience known at Toyota as "kan-kotsu" or "intuition and skills."

Inspections to ensure the highest possible quality

The final inspection is a crucial step to ensure that the Century achieves the highest level of quality. Two types of illuminations are used to inspect the quality of the carefully painted surfaces.

First, the way fluorescent lights reflect off the paint is checked. This is used to check for any surface variances and whether the character line is perfect.

Next, artificial sunlight is used to carefully evaluate the car in situations similar to where it will actually be used, mainly outdoors. This artificial sunlight inspection is carried out on every single car produced. This is the level of inspections required to ensure that each Century achieves the finest standards possible, without stinting on either time or effort.

-

-

- Fluorescent light inspection environment

-

-

-

- Artificial sunlight inspection environment

-

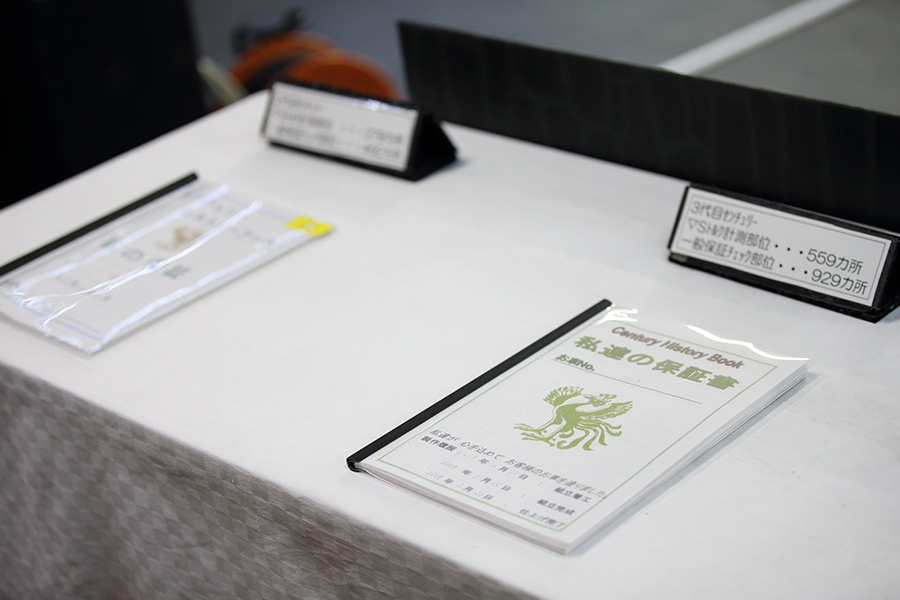

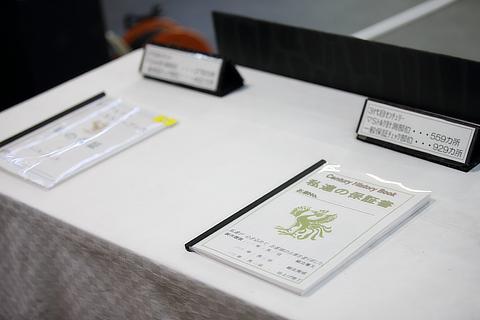

Evidence of a car without compromise

Starting with the second generation, history books for each individual car are kept at the Century plant. These books contain the records of the inspections performed after each process, including the name of the person supervising the inspection and the date. The Century is a car built by hand, taking time and care in its production, so naturally the path to completion for each vehicle is carefully recorded.

Guardians of tradition and quality

The craftsmen take pride in their car's history, which spans over fifty years, and are very particular about their skills. A Century is not completed through mere mechanical work. It is the craftsmen who shoulder the weight of long tradition and who have trained for years before they can work on the car, and who are the ones who can painstakingly craft an automobile fit for its customers. The dignity and the prestige of the Century have been refined and polished here at this manufacturing plant, and here these traditions shall live on.