Jul. 17, 1974

GENERAL PURPOSE INDUSTRIAL ROBOTS

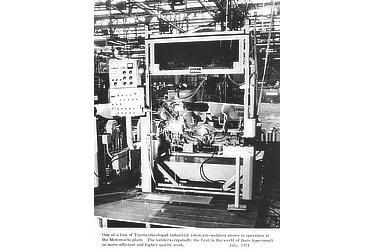

ARE HANDLING ARC-WELDING AT TOYOTA PLANTS

Improved Quality, Efficiency Result from New Applications

TOKYO―Toyota Motor Company engineers have successfully adapted industrial robots for the regular production line arc-welding of heavy steel plates and components. The development is reportedly the first of its type in the world.

Two welding methods are generally used at auto factories―spot welding of vehicle bodies and arc welding of heavier steel plates. Toyota now uses approximately 20 industrial robots for spot welding and has been using special machines for automated arc welding since 1955. Two years ago, an accelerated R & D program was set up to create or adapt industrial robots for production line arc welding.

Automakers throughout the world have long desired to use general purpose industrial robots for arc welding, but the enabling technology was lacking. The need became more evident with increased diversification of car models and the resulting occasional fluctuations in car output.

Toyota is using the equipment in several ways and plans a number of new applications. For example, two axle housings of different shapes are now being automatically welded at the Headquarters plant near Nagoya. Rear axle housings for the Toyota Corona SL will soon be produced in similar fashion at the Motomachi Plant.

The industrial robots being used in the new program are capable of 5 types of movements―expansion/contraction, vertical and body-turn, and turn and twist of a wrist-like extension. These 5 movements can be utilized and controlled in any combination.

- Toyota anticipates that industrial robots―some of them adapted to use methods developed by the company―will increasingly replace single function machines in a variety of industrial fields because of the following 6 advantages

-

- Better adaptability to car output fluctuations.

- Shorter lead time.

- Better product quality than with manual welding.

- Operators are freed from such dangers as sparks and smoky flashes.

- Shorter welding time (1/10th of manual welding time).

- No need for skilled labor.