Nov. 28, 1974

TOYOTA PRESS HARDENS RING GEARS WITH INDUSTRIAL ROBOT

Unique Method Results in Superior Vehicle Parts

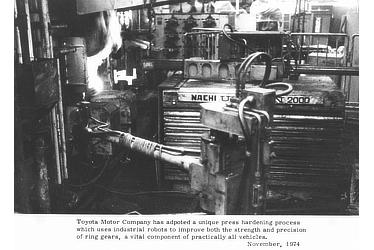

TOKYO―The Toyota Motor Company has revealed a unique press hardening process which uses industrial robots to improve both the strength and precision of ring gears, a vital component of practically all vehicles.

The new automated manufacturing system―developed in close cooperation with the Fujikoshi Company―will have wide application in the international automotive industry.

Press hardening is an advanced forging process in which ring gears cemented at an ultra-high temperature of 920°C are removed from a cementation furnace and immediately pressed to prevent any change of shape during cooling.

The process of press hardening is indispensable for achieving precision, great strength, and dimensional stability in ring gears. Although the standard method is in use at a number of factories around the world, many critical factors have until now combined to prevent its automation.

The innovative new method does away with the need for highly trained specialists to do complicated manual processing in the high heat and humidity necessary to produce perfect ring gears. The equipment is already in operation at 2 Toyota plants.

A unique industrial robot programmed to remove ring gears from the special furnace is at the core of the system. It removes two gears simultaneously and places them on a stand, using four basic motions. Another automated device places the gears into a press hardening machine.

All modules of the system are designed with great emphasis on safety and full automation. It is not necessary for operators to be near the equipment while it is functioning. Tests have shown that the ring gears produced are superior in many respects.