Aug. 23, 1973

TOYOTA WILL INVEST ¥20 BILLION TO ASSURE

"ZERO-POLLUTION" AT ITS PLANTS

Comprehensive Environmental Protection Program May be Industry's Best

TOKYO―Toyota Motor Company has announced that, by the end of 1976, it will have invested a total of approximately ¥20 billion ($77,000,000) in a multi-faceted anti-pollution and environmental protection program designed to make its plants virtually pollution free.

The huge investment is being made to further enhance Toyota's reputation among neighboring communities of a "Corporate Good Citizen" as well as to actively promote the creation of a necessary cleaner community environment.

To achieve this, the company plans to accelerate equipment investments and reinforce the technical staff now assigned to anti-pollution activities.

Strengthened anti-pollution efforts under the new policy will be implemented in the following major fields: (1) air pollution, (2) water pollution, (3) industrial wastes, (4) noise, and (5) "greening" of the environment.

Toyota has to date attached very great importance to the construction of completely pollution-free factories, such as the Myochi Plant and the Shimo- yama Plant.

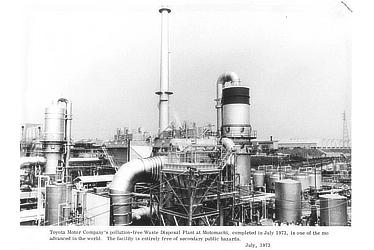

In recent months, Toyota has also erected a pollution-free, comprehensive waste disposal facility―believed to be the world's largest and most advanced for use by private industry―on a site adjacent to the Motomachi Plant in Aichi Prefecture.

- The fundamental anti-pollution strategy adopted by Toyota can be summarized as follows

-

- To be actively involved in bettering community environment under the motto of "To be in harmony with the community, a corporation must start with efforts to create a cleaner environment."

- To be dissatisfied with things as they are, but to exert an all-out effort to promote long-term anti-pollution measures.

- To urge all Toyota group companies to cooperate in anti-pollution activities, because a single corporation will face difficulties in fighting independently the large and very complicated problems of industrial pollution.

The funds that Toyota will invest in its anti-pollution program this year are expected to be sixty one times those of 1967, when the Fundamental Anti-Pollution Law was enacted. Toyota now has approximately 200 anti-pollution specialists on its payroll.

- Current status of Toyota's factory anti-pollution activities

- Air pollution

- Low sulphur content heavy oil is used in all applications,

- Dust collectors and cast-metal back filters have been installed,

- A total of approximately ¥3 billion has been invested in the above measures.

- Water pollution

- Comprehensive wastewater treatment facilities have been constructed at each Toyota plant.

- A total of approximately ¥3.5 billion has been invested in the above.

- Treatment and recycling of industrial wastes

- A urethane incinerator has been constructed at the Tsutsumi Plant,

- Three rotary kilns have been constructed at the Motomachi Plant,

- An isolated underground dump has been constructed at the Motomachi Plant.

- A waste treatment and disposal center has been constructed at the Motomachi Plant.

- Many other "safe-type" incinerators have been constructed,

- A total of approximately ¥1.4 billion has been invested in the above.

- Further, Toyota is now experimenting with methods to recycle industrial wastes. These include

-

- Recycling used tires into paving material;

- Recycling waste oil into new forms of fuel;

- Recycling wastewater for re-use;

- Recycling waste plastics into some constructive use.

- "Greening" of the environment

Toyota has been actively promoting the "greening" of the environment. Every time a new plant has been constructed, Toyota has planted a variety of trees and shrubbery around the new site and has created small park areas within the area.

- Myochi Plant, a model "zero-pollution" plant

The Myochi Plant―the initial stage of which was recently completed―will be Toyota's first model of a "zero-pollution" plant. Approximately 30% of total construction costs for the first stage were allocated to protection of the environment. Producing primarily cast-metal component parts, the Myochi Plant, when completed, will have an image quite different from plants making similar products, in terms of its anti-pollution concept and the methods used.

- Details of the advanced anti-pollution concept of the Myochi Plant, together with facts on its construction, are listed below

-

- Air pollution

-

- The plant buildings are windowless,

- Low sulphur content heavy oil is used throughout.

- Attempts have been made to switch to other sources of energy (electricity or gas),

- Dust collectors and hoods have been added to all equipment that discharges or collects soot and dust.

- Water pollution

-

- Comprehensive wastewater treatment facilities have been constructed.

- Sewage pipes and rain water pipes have been separated.

- Large-capacity sewage reservoirs and terminal rain water reservoirs have been constructed.

- Industrial wastes

-

- Space for waste sand and residual soil dumps has been secured within the plant.

- Sludge and other industrial wastes are treated and disposed of at the comprehensive waste treatment and disposal facility located within the Motomachi plant.

- Noise

-

- All production facilities have been equipped with vibration-proof materials and sound-absorbing walls or screens.

- Low-noise level devices have been incorporated in power-generating equipment.

- Buildings are windowless and noise-generating equipment is located in the central part of every building.

- "Greening" of

the environment -

- Approximately 3,000 trees have been planted around the perimeter of the site and green belts ranging is width from 20 to 30 meters have been provided elsewhere in the plant site.

-

- Anti-pollution measures planned for other plants in the near future

-

- Air pollution

-

- Addition of dust collectors to dust-generating equipment and facilities, the possibility of indoor dust collection;

- Removal of windows from plant buildings;

- Switches to alternate energy sources, such as electricity and gas;

- Water pollution

-

- Separation of rain water pipes and wastewater pipes;

- Treatment and disposal of wastewater at the source;

- Development and installation of production equipment and facilities that will not discharge waste- water;

- Recycling of wastewater and minimizing of waste- water discharge;

- Centralizing of sewage treatment with respect to company dormitories and apartment buildings;

- Incineration of sludge and liquid wastes where feasible;

- Industrial wastes

-

- Burial of heavy metal-contining materials in isolated dumping areas;

- Securing of space for additional waste treatment facilities;

- Development and installation of production processes and equipment that will not generate wastes;

- Recycling of industrial wastes;

- Noise

-

- Development and installation of new mufflers and sound-absorbing equipment;

- Changing of facility placement at existing plants;

- Removal of windows from plant buildings;

- "Greening" of

the environment -

- Accelerated effort toward "Greening of the plant site."