Jul. 27, 1982

TOYOTA DEVELOPS FIRST CERAMIC-FIBER-ALLOY AUTO PARTS

TOKYO―TOYOTA MOTOR CORPORATION recently announced the world's first FRM (Fiber Reinforced Metal) automobile parts. FRM is widely regarded as a material of the future and worldwide attention has been focused on attempts to develop practical applications for it

The FRM developed by Toyota has a completely new structure, in which aluminum is reinforced with an alumina-silica ceramic fiber. Toyota calls it a "CERAMIC FIBER ALLOY." This new material is created by reinforcing metal with strong fibers to provide high strength and hardness, low thermal expansion, and superior wear resistance.

In the past there have been problems with the compounding technology necessary to reinforce metal with fibers; and a similar substance used for the Space Shuttle's frame is another practical application to date. Consequently, Toyota's success in perfecting its CERAMIC FIBER ALLOY for heavy-duty, mass-produced auto components is a revolutionary technological discovery of worldwide significance.

Toyota's CERAMIC FIBER ALLOY was developed jointly with ART METAL MFG. CO., LTD. The application of this technology to automobile parts utilizes the advantages of the high strength of the new alloy and its superior durability against friction and heat. Another major merit is processing ease.

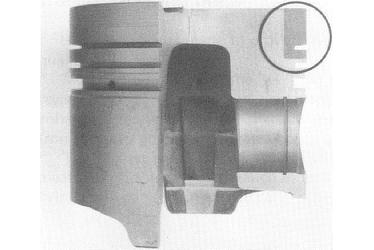

Toyota will be using the material for diesel piston ring grooves, instead of the cast iron insert used currently. This will provide improved durability at high temperatures, greater abrasion resistance and more cooling effect. The result will be better engine performance, lower noise, higher fuel efficiency, and less oil consumption. Toyota is now researching ways to expand the application range of this new material, and is concentrating its efforts to develop other new materials to introduce better cars for tomorrow.

CERAMIC FIBER ALLOY Piston