Oct. 29, 2013

Toyota Honored For Reducing, Reusing, and Recycling

Toyota City, Japan, October 29, 2013―Toyota Motor Corporation was honored this month for its ongoing efforts to promote a sustainable society by reducing, reusing and recycling resources.

At this year’s 3Rs (Reduce, Reuse, and Recycle) Awards hosted by Japan’s Ministry of Economy, Trade, and Industry (METI) 3Rs Promotion Council, Toyota and Toyota Tsusho Corporation shared the 2013 Prime Minister’s Prize.

Separately, Toyota and Sumitomo Electric Industries, Ltd. shared a Rare Metal Recycling Award from the Japan Environmental Management Association for Industry (JEMAI) presented earlier this month at the Awards for Resources Recirculation Technologies and Systems. The award, announced on October 11, recognized the companies’ jointly developed system for recycling the rare metal tungsten.

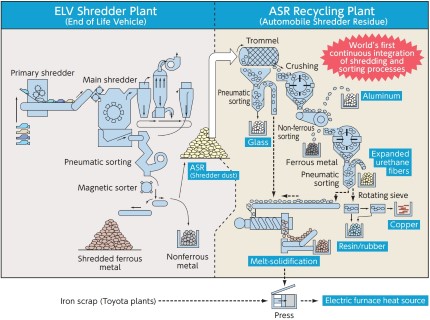

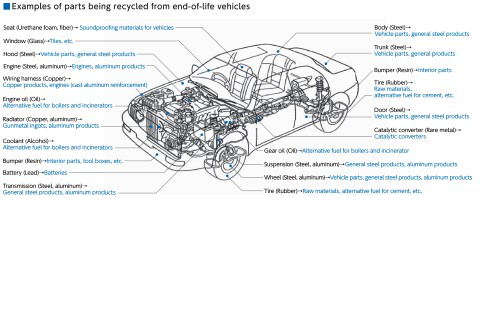

Toyota was one of the first automakers to respond to the implications of mass production and disposal of vehicles. In 1970, Toyota and Toyota Tsusho Corporation founded Toyota Metal Co., Ltd., the first end-of-life vehicle shredding plant established by an automaker. The Toyota Group (consisting of 17 companies including TMC and Toyota Tsusho Corporation) has remained committed to the responsible disposal of end-of-life vehicles, and has developed a wide variety of world-first recycling technologies and systems to recover materials.

NiMH Battery Reuse and Recycling

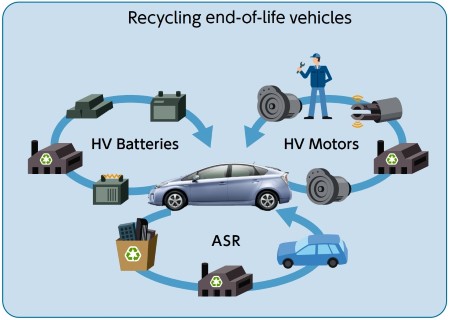

Since 1998, Toyota has recovered NiMH batteries from approximately 30,000 vehicles, equivalent to 80 percent of all end-of-life hybrid vehicles in Japan. Until recently, these batteries could only be recycled as a raw material for stainless steel. Thanks to collaboration with Sumitomo Metal Mining Co., Ltd., new methods for sorting and extracting nickel content have been developed. In 2010, this led to the establishment of the world’s first business to reuse nickel from used NiMH batteries in the manufacture of new NiMH batteries. In 2012, Toyota became the first automaker to develop technology allowing recovered NiMH batteries to be combined and reused in stationary rechargeable battery systems; sales to Toyota dealers by Toyota Turbine and Systems, Inc. began in 2013.

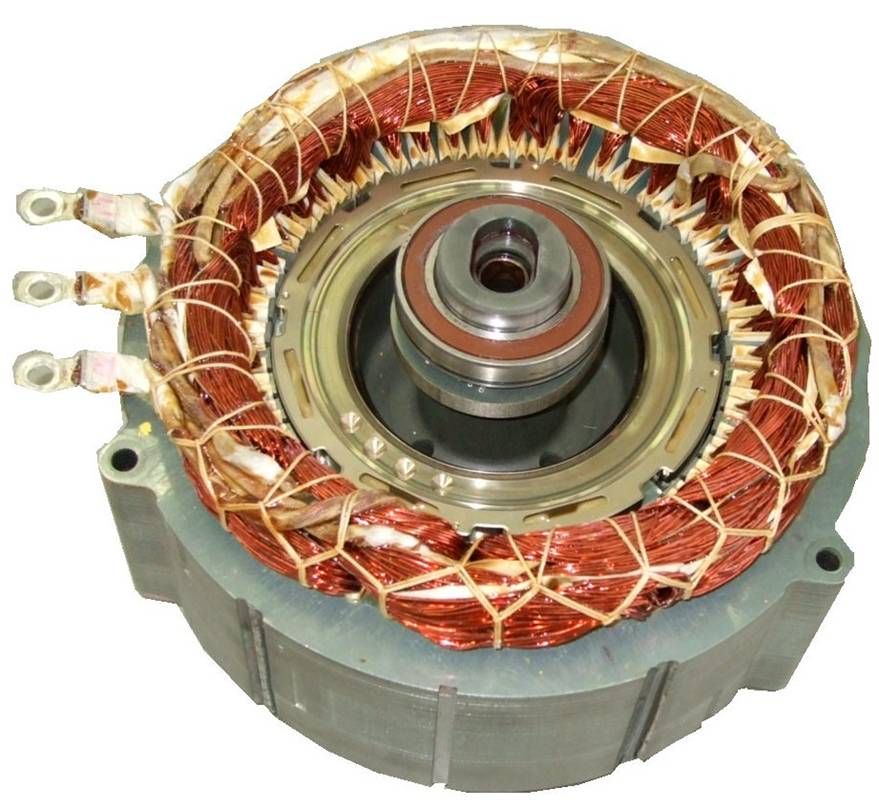

Motor Magnet Recycling

Toyota is committed to utilizing the planet’s scarce natural resources as effectively and efficiently as possible. In 2012, Toyota created the world’s first system for recycling neodymium and dysprosium, two rare earth metals used in magnets of hybrid vehicle motors.

Toyota is also working to recycle rare metals that are used in non-hybrid vehicles. In 2010, Toyota teamed up with Sumitomo Electric Industries to establish a business focused on recycling tungsten, which is most commonly used to produce highly resilient carbide tools. The system combines processes for sorting and collecting scrap from cemented carbide products with new, world-first recycling technology to enable 100 percent recovery and recycling of tungsten in cemented carbide scrap. To date, the venture has recycled 75 tons of tungsten.

Toyota's Recycling Initiatives

|

Year |

Milestone |

Details |

|

1970 |

Toyota Metal Co., Ltd. established to meet future demand for responsible disposal of end-of-life vehicles |

• First automaker to establish a recycling company • Approx. 6.5 million vehicles recycled between 1972 and 2012 |

|

1973 |

Toyota Chemical Engineering Co., Ltd. established to process and recycle cutting oil from Toyota production plants |

Established by Toyota Tsusho Corporation; 30,000 kL of waste oil processed and recycled between 2008 and 2011 |

|

1985 |

Toyotsu Recycle Corporation established to recover and recycle precious metals from exhaust gas catalysts |

Established by Toyota Tsusho Corporation; approximately 16 million catalysts recycled between 1985 and 2012 |

|

1992 |

Toyota Environment Committee established |

Chaired by TMC president |

|

1996 |

Bumper recycling across Japan commences |

Approximately 10 million recycled between 1996 and 2012 |

|

1998 |

Automobile Shredder Residue (ASR) recycling plant established |

• Established at Toyota Metal Co., Ltd.

• World’s first dedicated ASR plant

|

|

End-of-life hybrid vehicle NiMH battery collection and recycling commences |

Approximately 30,000 collected between 1998 and 2012 |

|

|

2001 |

Automobile RecycleTechnicalCenter established |

Established at Toyota Metal Co. Ltd.; first automaker to establish an independent recycling research institute |

|

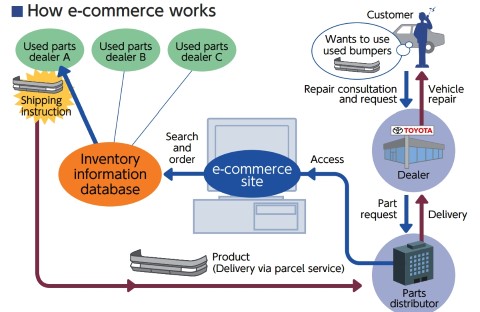

Ecoline Corporation, a used parts sales network operator, established |

Established by Toyota Tsusho Corporation; approximately 200,000 used parts handled annually |

|

|

Parts e-commerce system introduced for Toyota parts distributors throughout Japan |

Approx. 600,000 used parts sold between 2001 and 2012 |

|

|

2003 |

Toyota Recycling Vision formulated |

Sets targets for 2015 |

|

“Raum” model launched |

Incorporates Toyota’s proprietary “Design for Recycling” (DfR) features |

|

|

Bio-plastics used in parts for the first time |

World-first |

|

|

2005 |

Aluminum recycling business established at Toyota production plants |

Expanded to 13 plants worldwide; approximately 2.5 million tons recycled between 2005 and 2012 |

|

2007 |

95% vehicle recycling rate achieved |

- |

|

2009 |

Recycling guidance commences in countries where hybrid vehicles are sold |

Aiming for development of NiMH battery collection systems outside Japan |

|

2010 |

Battery-to-battery recycling of hybrid vehicle NiMH batteries commences |

World-first |

|

Tungsten recycling system launched |

World-first; approximately 75 tons recycled between 2010 and August 2013 |

|

|

2011 |

99% vehicle recycling rate achieved |

- |

|

2012 |

Magnet-to-magnet hybrid vehicle motor magnet recycling system launched |

World-first |

|

2013 |

System for reusing NiMH batteries in stationary rechargeable batteries launched |

World-first |

|

Redesigned “Sai” dedicated hybrid sedan launched |

Achieved 20 percent usage of Ecological Plastic and recycled resin materials |

|

|

Toyota wins JEMAI Rare Metal Recycling Award |

First automaker to win the award |

|

|

Toyota wins Prime Minister’s Prize in the 3Rs Awards |

First automaker to win the award |

Additional Information

Toyota's environmental initiatives

http://www.toyota-global.com/sustainability/report/er/

3Rs Promotion Council homepage

http://www.3r-suishinkyogikai.jp/ (Japanese only)

JEMAI homepage

http://www.jemai.or.jp/english/index.html

Toyota's sustainability report on vehicle recycling

http://www.toyota-global.com/sustainability/report/vehicle_recycling/