Aug. 22, 1977

FULL-MODEL CHANGES OF CARINA AND CELICA UNVEILED

29 Variations Meet Tough 1978 Emissions Standards With Toyota TGP Combustion Method

TOKYO Toyota Motor Co., Ltd., and Toyota Motor Sales Co., Ltd., announced the nationwide sale today of full-model changes of the Carina and Celica, the first since these models were introduced to the maket in December 1970, although the Carina Hard-top was added to the line in December 1972, the Celica Liftback in April 1973 and the Carina Van in December 1975. Twenty nine variations of the new models meet Japan's tough 1978 emissions standards through use of the Toyota TGP (turbulence generating pot) combustion method in the 12T-U type engine.

In developing the full-model changes of the Carina and Celica, Toyota engineers paid careful attention to social demands in the areas of meeting emissions standards, providing greater safety, and conserving natural resources and energy. They also adopted a theme of "high quality, and high performance" for working to improve further the running performance, comfort and operatability of the Carina and Celica, features which car users have always demanded of automobiles.

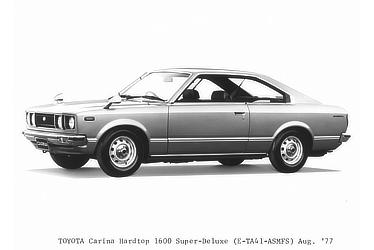

For the Carina, Toyota planners aimed at designing a "dynamic, family car" with a clean appearance emphasizing lightness and smartness which would appeal to a wide range of customers. In response to more diversified demand, moreover, the new models have been provided with more variations to choose from, and come more fully equipped than previously. In the Carina Van, the rear quarter window has been enlarged to provide a smarter appearance, and luggage space has been widened for greater carrying capacity.

For the Celica, meanwhile, Toyota planners aimed at designing a "more individualistic specialty car," and the Celica incorporates a boldness and freshness in styling which reflect a careful study of space dynamics. Also, its utility space has been widened to make it fitting for multi-purpose uses.

Of the Carina and Celica models put on sale today, 15 variations of the Carina (9 sedans, and 6 hard-tops) and 14 variations of the Celica (8 coupes, and 6 liftbacks) a total of 29 variations―are mounted with a 12T-U type engine (1,588cc) which meets Japan's tough 1978 emissions standards through use of the Toyota TGP combustion method. This method is a new emissions cleansing method combining the best features of the Toyota lean air-fuel mixture combustion system with those of the Toyota catalyst method. The air-fuel mixture for the 12T-U type engine is controlled at the ideal mixture ratio with this method, and the method includes an EGR (exhaust gas recirculating) system, a secondary air injection device, an oxidizing catalytic converter and a powerful spark device.

In the TGP combustion method, the air fuel mixture is ignited quickly by a strong flame jet from the TGP located in the combustion chamber, which reduces the amount of NOx generated. Also, even if large volumes of exhaust gases are recirculated (via the EGR) or if the air-fuel mixture is made lean, ignition and combustion both remain stable. These two features reduce greatly the amount of NOx generated in the combustion chamber. CO and HC, meanwhile, are cleansed through use of a reliable, durable oxidizing catalytic converter.

In the TGP combustion method, moreover, the air fuel mixture is controlled with great precision to obtain the ideal mixture ratio under a variety of driving conditions. Ignition timing is also controlled for maximal effect, which contributes to superior fuel efficiency and drivability.

With the marketing today of these full model changes of the Carina and Celica, the total number of Toyota vehicles now complying with Japan's 1978 emissions standards is 129 versions of 8 models. These include the recently introduced Crown, Mark II and Chaser models using the Toyota 3-way catalyst system, and the Corona, Corolla and Sprinter models using the TGP combustion method.

In addition to the 12T-U type engine, which meets the 1978 emissions standards, the Carina and Celica series of passenger cars have four other types of engines: the 2T-GEU type (1,588cc, DOHC, with electronic fuel injection device), the 3T-U type (1,770cc), the 18R-U type (1,968cc), and the 18R-GU type (1,968 DOHC), all used to meet Japan's 1976 emissions standards with the Toyota catalyst system. The 2T-GEU type engine had not been used before in either the Carina or Celica models, the 3T-U type had not been used in the Celica and the 18R-U type had not been used in the Carina. The Carina Van is mounted with either the T-J type (1,407cc) engine or the 2T-J type (1,588cc) engine.

Moreover, in order to meet the increasing trend among customers in the small-car market toward higher-class cars, a high-grade "SE''type has been added to both the Carina and the Celica, and an "XT'' type has been added to the Celica, thus making both series fuller. As a result, a total of 65 versions of the Carina and 64 versions of the Celica are now available: the Carina has 3 versions of the 2-door sedan, 27 versions of the 4-door sedan, 28 versions of the hard-top and 7 versions of the van; the Celica has 33 versions of the coupe, and 31 versions of the liftback.

Attached are an outline of the Toyota TGP combustion method and information sheets on emissions data and the fuel efficiency performance of the Carina and Celica.

TOYOTA TGP COMBUSTION METHOD

-

What is the Toyota TGP Combusion Method?

The Toyota TGP (turbulence generating pot) combustion method is a new emissions cleansing system. Basically, Toyota engineers have focused their attention on the special combustion characteristics of a combustion chamber fitted with a TGP, and have combined an EGR system, a secondary air injection device, an oxidizing catalytic converter and a powerful spark device together with a 12-T type engine using a lean combustion method for controlling exhaust emissions.

-

Special combustion characteristics of TGP combustion chamber.

- A strong flame-jet results from combustion in the TGP. This flame-jet causes turbulence in the air-fuel mixture, which quickens combustion but keeps it stable.

- Quick, stable combustion shortens the time at which combustion gases are sustained at high temperatures. Also, since the maximum combustion temperature is low, there is less NOx generated than in combustion chambers without a TGP.

- Since there is little change in torque in a combustion chamber with a TGP compared to one without a TGP, the allowable combustion limits are greater in the former even when large volumes of emissions are recirculated, or when the air-fuel mixture is made lean.

-

Cleansing of emissions in TGP combustion method.

-

Not only is there basically less generation of NOx in the TGP combustion method, but in order to reduce NOx:

- an appropriate amount of emissions, depending on driving conditions, is recirculated to the intake system via the emissions gas recirculating device, and

- the ideal air-fuel mixture is provided, taking emissions, fuel efficiency and drivability into consideration.

-

Not only is there basically less generation of NOx in the TGP combustion method, but in order to reduce NOx:

The following air-fuel mixture and volumes of recirculated emissions are appropriate for the particular driving conditions.

| Driving condition | Air-fuel mixture | Volume of emissions recirculated |

|---|---|---|

| Accelerating | Close to theoretically Ideal mixture | Large |

| Constant speed driving | Lean mixture | Small |

During acceleration, when torque and output are required, NOx is reduced by recirculating a large volume of emissions while controlling combustion near the theoretically ideal air-fuel mixture ratio. During normal operation, however, when relatively little output is needed, NOx is reduced by recirculating a small volume of emissions while controlling combustion of a lean air-fuel mixture that is effective for providing good fuel efficiency. Also, since a lean air-fuel mixture is used more frequently in this method, there is little generation of CO and HC.

-

Additional emissions cleansing devices

-

Oxidizing catalytic converter

This device oxidizes CO and HC and turns it into CO2 and H2O by an oxidizing catalyst.

-

Oxidizing catalytic converter

-

Secondary air injection device.

By using the pulsating action of the exhaust stroke, this device takes air in through the air cleaner and introduces fresh air into the hot emissions in the exhaust port. CO and HC are oxidized in the catalytic converter and the exhaust manifold.