Sep. 12, 1973

TOYOTA DELIVERS FIRST OF 10 EXPERIMENTAL SAFETY VEHICLES

TO JAPANESE GOVERNMENT

¥2 Billion Spent in 3-Years on Researching Advanced Concept ESV Prototypes

TOKYO―Toyota Motor Company on September 6th delivered the first of 10 highly advanced Experimental Safety Vehicles (ESV's) to the Japanese Government, with the remainder of the secondary prototypes to be completed for delivery by the end of November. The vehicles were developed by the company as part of the Government's comprehensive ESV program.

Over ¥2 billion (approximately US$7½ million) has been spent on the development by Toyota during the past 3-years. Forty company engineers have been exclusively engaged since early 1971 on aspects of the program.

Approximately 100 research prototypes have been test-crashed during experiments on such factors as braking performance, steering stability and driver visibility in pursuit of the ideal "Safety Car."

Two goals were paramount in the exhaustive studies of driving safety undertaken by scientists and engineers during development of the Toyota ESV: (1) To satisfy and even exceed official Japanese Government ESV specifications with regard to "accident prevention"; and (2) To satisfy and exceed the Japanese Government's (and all other existing) ESV standards with respect to vehicle safety during collision.

Toyota claims that the prototypes delivered and in final assembly will satisfactorily fulfill and surpass all specifications. Company officials state that the Toyota ESV has been developed not only to meet the goals set by the Government, but its own high ESV development aims.

The firm's Experimental Safety Vehicles were created solely as experimental units in the important search for the best possible automotive safety features, without regard to cost or the feasibility of starting early production of the models or variants.

However, a great deal of the valuable technical knowledge obtained during the all-out research program is already being reflected in new Toyota models appearing on the market.

Good examples of "fall-out" from the program are the "Electro Sensor-Panel" ("OK Monitor") and "Shock Absorbing Bumper" introduced last week on models in the new Toyota Corona Series.

Many new features resulting from the development project will also be incorporated into new Toyota models now being designed or in the prototype stage.

-

Toyota ESV Development Goals

- To satisfy and even excel official Japanese Government ESV specifications with regard to accident prevention.

- To satisfy and exceed the Japanese Government's (and all other existing) ESV standards with respect to vehicle safety during collision.

-

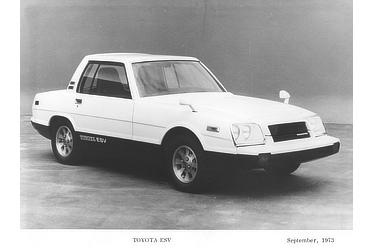

Toyota ESV Model Description

- Dimensions

- Over-all length4,300 mm,Over-all width1,800 mm,Over-all height1,360 mm

- Seating Capacity

- 2

- Engine

- 1,600 cc 102 HP (gross)

- Transmission

- Electric remote-control type 3-speed automatic

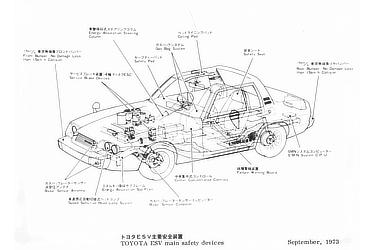

- Brake System

- (Service Brake Devices) disc brakes on all four wheels, with high-performance oil booster and four wheel Electronic Skid Control (ESC) System, to assure stable braking performance with minimal forward movement under all road conditions.

Lighting Equipment- Headlights

- Beam lamps are linked to a 4-mode automatic switching mechanism sensitive to the speed of the vehicle, which provides a lighting level most appropriate for each speed (Speed Sensitive Head Lamp System). A "fail-safe" reserve lighting system is also incorporated, which lights automatically upon lamp failure.

- Signal Lamps

- A dual-level illumination switch is provided (different light intensities can cope with both day and night driving conditions).

- Wiring

- SMN (Single-wire Multiplex Network) System is used. To avoid overloading of electrical circuits by the numerous electronic and electrical control devices, as well as to eliminate any potential fire hazard, a unique computer control system has been adopted.

- Failure Warning Board

- Scores of potential trouble areas (e.g., brakes, lighting, engine, etc.) are linked to warning lamps in a central console.

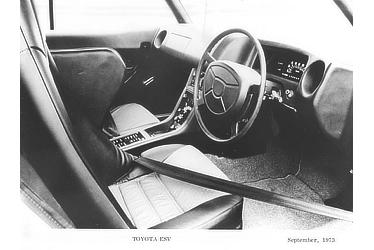

- Interior

-

- Safety pads are used on all useful interior surfaces.

- The simplified Center Concentrated Controls are designed and arranged to meet all ergonomic requirements.

- Body Structure

- An Energy Absorption Sub-Frame is attached to a uni-frame (to absorb 67% of the energy released in an 80 km/h frontal impact). Passenger compartment distortion is less than 5-inches in impact at all collision speeds specified.

- Bumpers

- Front and rear bumpers incorporate silicone-type shock absorbers which completely absorb crash energy and cushion the body against harm in collisions at less than 15 km/h.

In collisions at 80 km/h, they absorb 13% of the energy generated.

To protect pedestrians, bumpers are covered with soft urethane foam rubber.

- Occupant Protection Equipment

-

Energy absorption interior materials (e.g. safety pads, etc.) are used throughout.

-

- Driver's Safety Seat

- Energy Absorption Steering Column, 2-point passive wrap belt (emergency lock)* and a Gas Bag System.**

-

- Passenger's Safety Seat

- Passive wrap belt and Gas Bag System.

- *

- The 2-point passive wrap belt (emergency lock) is keyed to the opening and closing of doors. The wearer moves freely during normal driving conditions, but is held firmly by the belt when a sensor triggers a warning signal at the moment of collision or overturning.

- **

- Installed in the steering wheel at the driver's position and in a safety pad at the passenger's position, the bags are activated by a Radar Sensor Computer which anticipates collisions by calculating the relative speed and distance from another object at speeds in excess of 30 km/h.

-