Dec. 13, 2017

The Story Behind the Birth of the Prius, Part 2

Solving each problem, one by one

At the Tokyo Motor Show in October 1995, the team exhibited the Prius concept car, based on the Toyota Energy Management System (EMS), as planned. Although interest was tepid among the general public, engineers from other car companies took a quiet, but keen, interest in the car. At around the same time, the team was working to finalize the prototype of the production hybrid.

Prius concept car

"It wasn't until around the beginning of November 1995 that we assembled all the parts into a car," says Ogiso. "But even though it was assembled, we couldn't get it to run."

This was the first time the team had ever tried to operate the new hybrid system, and they initially had trouble rooting out the cause of the malfunctions. They used analog testers and also analyzed digital signals on computers to work steadily in solving each individual problem.

"We began working on issues one by one on the test bench, but new issues kept cropping up," Ogiso recalls. "The prototype wasn't a tidy machine. The onboard computers should have been installed in a box, but we couldn't make one small enough at first, so we just lined up the parts on a big steel plate. Everyone called it the 'barbeque board'."

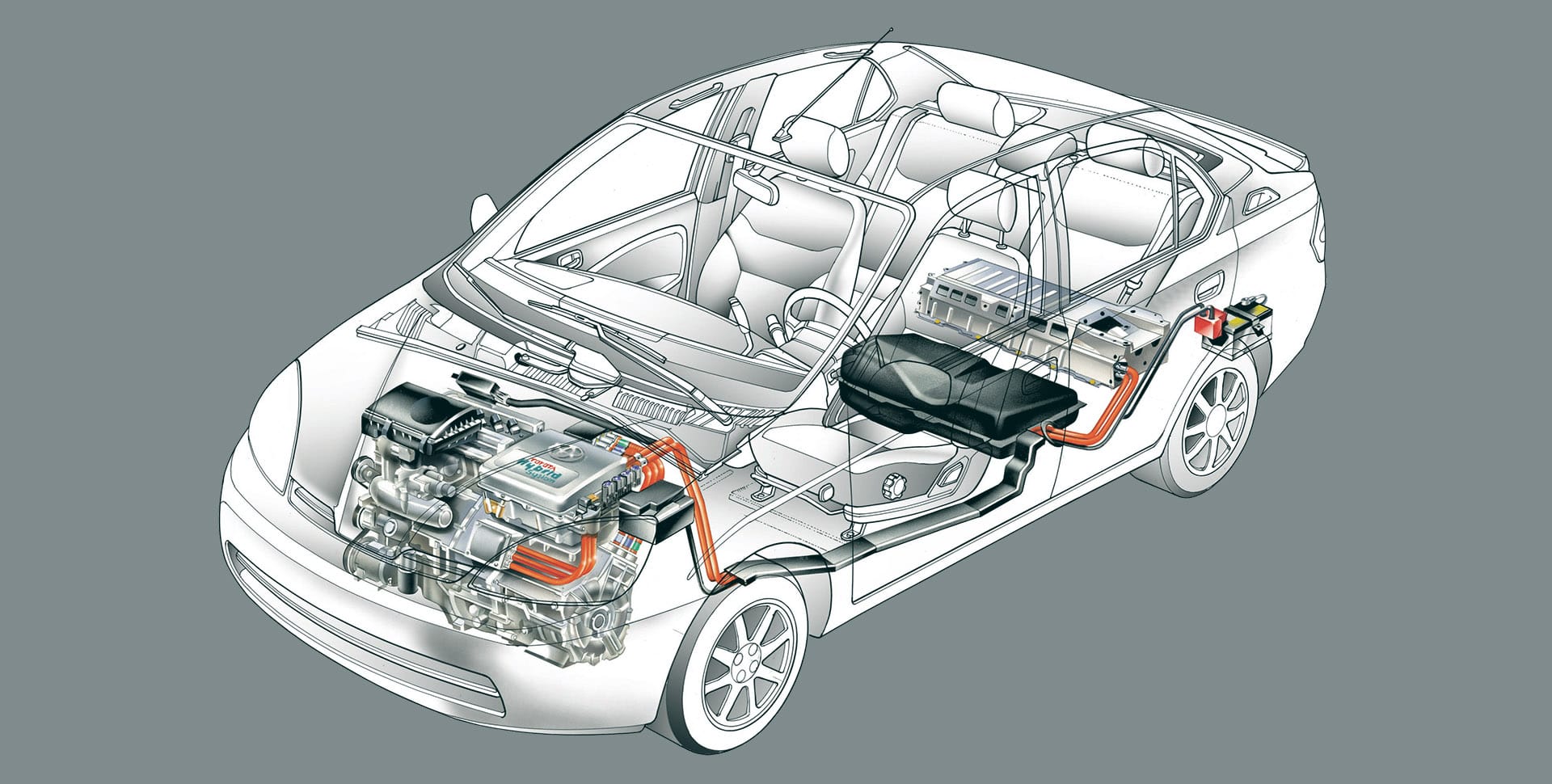

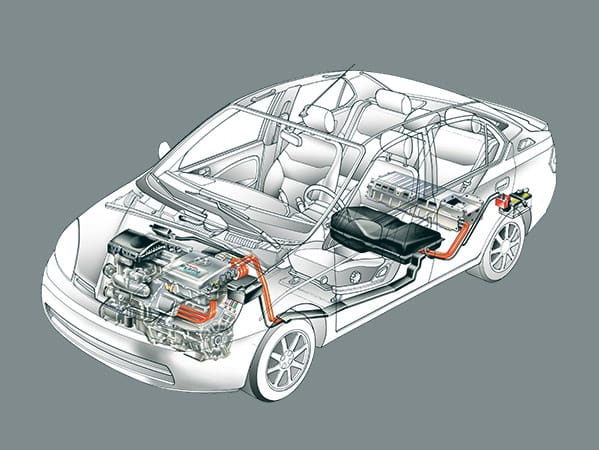

Even after tests were successfully completed on the test bench, many of the components failed when they were installed in the car. The challenge with the Toyota Hybrid System (THS) was the complexity of the drive system. There were various drive formats. Sometimes the car would drive using just a motor, and at other times, just the engine. There was another mode in which both motor and engine operated at the same time. The computer calculated the most efficient driving mode. There was never a simple reason or solution to address why the prototype was not operating. Pinpointing the cause of a problem typically involved checking different combinations of parts.

"It took us 49 days to get the prototype operating," says Ogiso. "Even then, the driving was awkward and inconsistent. After 500 meters, it just stopped altogether. Yet, it was very emotional for all of us to see it run and know that we had at least got it running before the end of the year."

Nonetheless, the prototype was a long way from production. The team still needed to achieve double the fuel efficiency of a conventional car, improve drivability, and ensure durability. Even with these challenges left to solve, it was time for the project to prepare for mass production. The team would have to increase development speed to meet the sales and production target by the end of 1998.

With time running out, the team was astounded by a management decision to accelerate the project by a year and aim for release in 1997.

The Third Conference of the Parties to the United Nations Framework Convention on Climate Change (COP3) was scheduled to be held in Kyoto in December 1997. Management had decided to time the Prius release to coincide with COP3 and leverage the wave of media attention that a hybrid car could garner around an environmental conference. The Prius represented a tangible solution to the need for a dramatic reduction in CO2 emissions. It was a global game-changer for the environment. However, another factor was even more significant.

"All the major carmakers were developing electrified cars," recalls Ogiso in explaining the biggest reason for the new target. "There were a lot of hybrid cars at the motor shows, and we knew that competitors were involved in R&D. In the annals of car history, there are many examples of companies falling victim to rivals after missing a narrow window of opportunity, even while in a hurry. The environment was a critically important theme to carmakers, and we couldn't afford to take second place."

Taking a prototype that could run only 500 meters and turning it into a production vehicle in two years was no easy task. The team still faced a mountain of problems to solve. The performance of the nickel-hydride batteries was half the estimated level, and their size was double the design. The hybrid system charged and discharged the batteries frequently, and the team had to prevent the memory effect from shortening the batteries' lifespan. During test drives, the batteries would frequently die, forcing a redesign in battery life control. Moreover, battery quality control would become more complex during mass production, when 240 cells would need to be connected in series.

Batteries weren't the only major issue. A core component of the inverter was a semiconductor module known as an insulated gate bipolar transistor (IGBT). The IGBT was designed to switch large amounts of current at high speed, but there was the challenge of overheating during operation. Since the module worked in conjunction with the engine, a source of heat, the team needed to find a cooling method. Bench tests, however, resulted in repeated overheating and explosions. For production, it would be necessary to both raise the switching speed and ensure breakdown endurance.

The team solved these difficult technical challenges but still faced an unsure road ahead.

"During test drives, we knew that the prototypes didn't have good fuel efficiency. In fact, fuel efficiency was worse than a standard Corolla," says Ogiso. "The new equipment we were adding was using a lot of electricity for cooling. The electrical load was about three times that of a normal car, which lowered the fuel efficiency. Finding ways to lower the load was a tough task."

For motor development, the team benefitted from experience with the RAV4 EV. Now, they needed to customize the design for mass production. For an EV, only the motor sat beneath the hood. The Prius required the motor to be installed alongside the engine. It would have to be ultra-compact to fit. The team chose a NZ-style engine designed for a compact car. The Atkinson cycle design improved thermal efficiency and raised fuel efficiency. Though engine output would be low, the motor could compensate to boost torque. During driving, however, there was excessive vibration when the engine restarted from a complete stop. The vibration was all the more noticeable because of the quiet motor operation in driving mode. This became a new roadblock to production.

Engine compartment of the first-generation Prius

"We had a lot of issues to solve," notes Ogiso. "Just when we solved one, another one cropped up, and we didn't see how we could meet mass production in two years. That's when we turned to a development method called simultaneous engineering (SE) to speed up the processes. It was a way to solve many issues at the same time. We collaborated with the production engineering divisions to ready the car for mass production, even from a stage where the car wasn't operating properly."

The Prius would ultimately be manufactured on a mass production line, so it was important to incorporate the needs of genba (on-site) production divisions from an early stage. This mitigated the need for unnecessary changes to the design at latter stages, when the design division sent drawings to the production divisions for review.

No turning back

In March 1996, veteran engineer Takehisa Yaegashi was appointed leader of the hybrid system team. Even with his talents to bolster the development structure, the G21 members were in a race against time. They weren't confident that the deadline at the end of 1997 could be met. Amid the anxiety, the development team was stunned by the company's announcement at a media briefing on March 25, 1997 at a hotel in Akasaka, Tokyo.

At a technology announcement for THS, President Okuda boldly announced in his opening remarks that Toyota had successfully developed a hybrid system as an answer to the 21st century's environmental problems. The press release promised about twice the fuel efficiency of a conventional car and a new hybrid model within the year. Ogiso couldn't conceal his surprise the next day when he saw the newspaper coverage.

"The media was reporting that THS could get 28 kilometers to the liter and the price would be ¥500,000 more than the Corolla even though we hadn't released any specific figures at the press conference," recalls Ogiso. "We hadn't yet reached 28 kilometers per liter, and we couldn't say at that time that it was attainable. The company had decided to launch in December 1997, and at that juncture, not everything was going according to plan. There was a point earlier in the project where we had asked management to postpone the launch if development became too difficult. But now that the schedule was announced to the public, there was no turning back."

By August 1997, testing was nearly complete. A dedicated line began producing prototypes at the Takaoka Plant from September. The engineers were reassigned to the plant to make design changes and pave the way for production. The design and development team had involved the production division in the project at an early stage, which kept the late-stage design changes to a minimum.

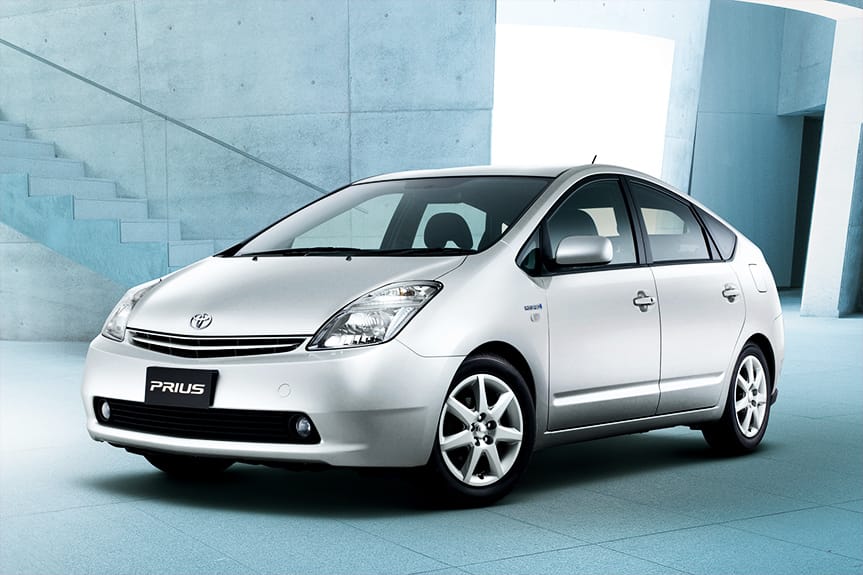

Just in time for the 21st century

The press conference to unveil the Prius was held October 14, 1997 at a hotel in Roppongi, Tokyo. The conference room was filled with not only auto industry journalists, but also the general media. The proudest accomplishment of the team was the achievement of 28 kilometers per liter under the Japanese 10-15 test cycle. They had met their promise of delivering double the fuel efficiency of a similar gasoline engine car. What's more, the price tag of ¥2.15 million was even lower than what the media had reported back in March.

First-generation Toyota Prius

The announcement sparked public interest in the Prius at the Tokyo Motor Show held from October 22, drawing throngs of visitors to get a glimpse of the car. The Prius was named Japan Car of the Year in 1997 by an overwhelming margin of nearly 200 votes separating it from second place. At the COP3 conference in December, the Prius was used to taxi participants between venues. The global media was captivated, peppering Toyota executives and engineers with questions about the car. A new advertising campaign accompanied the debut, with the catchphrase "Just in time for the 21st century" to emphasize the Prius's position as a car to usher in the next century. The G21 project had ended with a resounding success.

"The line-off ceremony went smoothly on December 10," says Ogiso. "Our original sales plan was 1,000 units a month in Japan. The initial orders were large, and we expanded capacity after that, averaging production of about 1,500 units a month for the first generation. We had no idea whether it would sell or not, so it felt good to see sales of over 1,000 units a month. We had originally planned to debut the Prius in Europe and North America from 2000 along with the partial redesign, so there was still a lot of work left after sales began. We had developed a hybrid from scratch in a little more than two years, so we thought the next model in two years' time would be easy. However, we needed to make the Prius ready for high-speed operation in Europe and for temperatures of up to 50 degrees Celsius in Death Valley in the United States. And with the partial redesign, we decided to make major changes to the hybrid system, so we didn't have the luxury of time."

Line-off ceremony for first-generation Toyota Prius

Hybrid car sales exceed 10 million units

The Prius remained in the spotlight after the launch, with orders in the initial month of sales reaching 3,500 units, three times the target. The ¥2.15 million price tag may have been less than the market expected, but it was significantly higher than other cars in its class. Despite this, the flood of orders reflected the excitement among environmentally conscious consumers.

The first completely redesigned Prius arrived in 2003, and the monthly sales target was reset to 5,000 units. Again, consumer clamor for the new model outstripped projections, with global monthly sales surpassing 10,000 units. Hollywood stars were seen arriving for red carpet events in their Priuses, further raising interest among consumers concerned about the environment.

Second-generation Toyota Prius

"The first-generation Prius made a splash, but it was still a niche car that was far from the mainstream," notes Ogiso. "There were discussions inside the company on whether we really needed to release a second generation. However, after listening to consumers, we realized that the reaction among consumers in the know (in regard to the environment) in Japan and the United States was positive. The second generation represented the next evolution of the hybrid system, improving both fuel efficiency and drivability, and succeeded in further raising the Prius's presence in the global market."

The development teams continued to develop the Prius, and by the fourth generation released in 2015, the car boasted fuel efficiency of more than 40 kilometers per liter. By then, nearly half the cars sold by Toyota in Japan were hybrid cars, and by the end of January 2017, cumulative Toyota hybrid car sales had exceeded 10 million units.

Fourth-generation Toyota Prius

"The acquisition and nurturing of core technologies through in-house creation made a big difference with profound benefits that can be seen to this day," says Ogiso in looking back on the Prius achievement. "When you have the same people working for years within the same company who develop a discerning eye for technology, it makes a tremendous difference in the product you deliver. The Prius development experience played a pivotal role in the development of the Mirai fuel cell vehicle launched in 2014. After working on projects for 20 years, you get an instinct for anticipating what needs to be done next. Looking back at those early days of my career working on Prius development, I recall the pure agony of the challenges we faced, and yet I feel the work continues today."

Present day

The Prius, having overcome so many challenges, turned 20 years old in 2017. The experience gained from acquiring and nurturing core technologies through in-house creation has contributed to the development of new technology in cooperation with suppliers. For the fourth-generation Prius, performance improvement and cost reduction of each unit was realized with the cooperation of various suppliers. The Prius has been beloved and fostered by so many drivers around the world and will continue to evolve as a pioneer paving the way for cars in the future. Drive on, Prius.

Satoshi Ogiso

Satoshi Ogiso was born in Tokyo in 1961. He joined Toyota Motor Corporation in 1983 and initially worked in the Chassis Engineering Division designing suspensions mainly for front-engine, front-wheel-drive vehicles. After working on advanced platform development, he joined the G21 project in 1993 as a founding member. He was involved in product planning and development of the first-, second-, and third-generation Prius as well as the Prius Alpha and Prius PHV. He also joined the iQ development team midway through the project. In 2007, he took charge of Aqua development as development leader from the product planning stage. He also served as the chief engineer for next-generation environmental cars (HV/PHV/EV/FCV). In April 2013, he was appointed managing officer of Toyota Motor Corporation, and in June 2015, he was appointed president of Advics Co., Ltd.

Satoshi Ogiso