Aug. 04, 2017

History of Toyota Hybrid System-Racing (THS-R)

THS-R: development starts

Although the Toyota Prius had been on sale since 1997, the earliest indication that Toyota's proprietary hybrid technologies could be adapted for racing came on 12 May 2005, when Toyota Motor Corporation determined that it would "consider the race activity that uses a hybrid system."

At that time, race cars with hybrid systems didn't exist and there were certainly no dedicated series in which to participate. So Toyota engineers began developing a dual-power system that was adaptable to different disciplines and would be acceptable to motorsport authorities.

Although similar in principle to Hybrid Synergy Drive for road-going cars, THS-R would have to be far more focused on the recovery of brake force energy in order to exploit it for accelerative power.

THS-R: 2006 Denso Lexus GS 450h

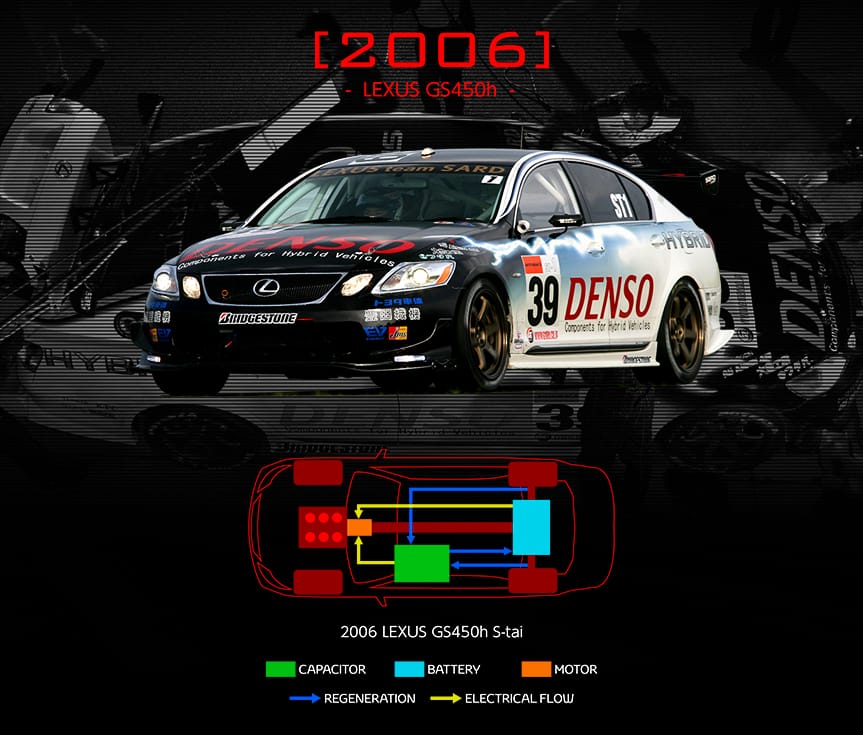

The first manifestation of a racing hybrid system arrived in the Lexus GS 450h entered by Toyota subsidiary Denso in the Tokachi 24-hour race in July 2006. This is the longest round of Japan's Super Taikyu, or S-Tai, endurance series.

Interestingly, the organisers recognised the imminent arrival of new technology in racing and established a Production-1 (P-1) category for hybrids and other environmentally considerate vehicles. So while the rear-wheel drive Lexus was officially entered in this new P-1 class it had actually been developed in line with regulations governing the ST-1 (3,501cc or higher) class.

The production-based Lexus GS 450h race car adopted a capacitor alongside its regular hybrid architecture and V6 petrol engine. The thinking behind this was that a hybrid racing system required the sort of rapid charging and discharging qualities that would be impossible for the standard nickel-metal hydride battery.

The maximum output of the entire hybrid system equalled 341bhp, the same as that of the production car. This was enough to see the Lexus finish the race trouble-free and in 17th position out of a total field of 33 cars.

THS-R: 2007 Denso Sard Toyota Supra HV-R

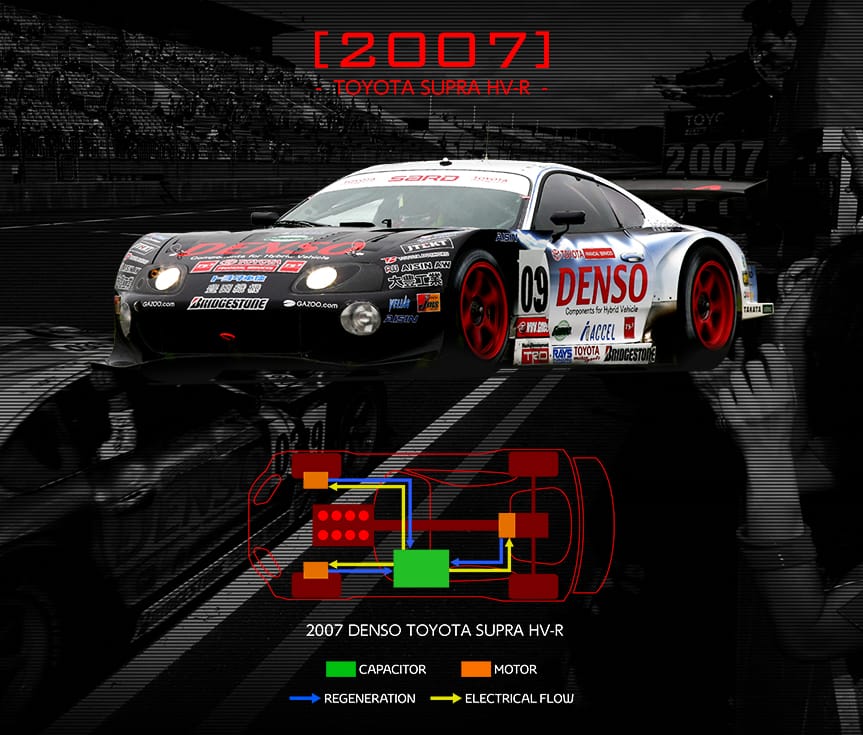

Having acquired a vast amount of valuable race data, the development team used this knowledge to create a purpose-built racing hybrid system for a return to the Tokachi 24-hour race in 2007.

The base vehicle this time was a GT500-specification Toyota Supra from the country's popular Super GT series. It retained the race car's naturally aspirated, 480PS 4.5-litre V8 but gained another 230PS through the inclusion of a 150kW motor/generator unit (MGU) across the rear axle and individual 10kW MGUs in each front wheel. Though the front wheels had relatively little power at their disposal, the Supra could now recover energy more efficiently from three separate sources.

As before, a fast-acting capacitor system was installed to store and supply electrical energy. But this time it replaced the battery pack, simplifying the overall architecture and leaving the Supra HV-R to tip the scales at an impressively low 1,080kg.

Despite adverse conditions that included intermittent rain, the four-wheel drive Supra HV-R ran trouble-free to complete 616 laps (1,944 miles) in the 24 hours. And what's more, it finished in first place overall, a resounding 19 laps ahead of the second-place finisher, securing Toyota's place in the record books as making the first hybrid-powered vehicle that won a racing competition.

Analysis after the event showed that although the Supra HV-R was much more powerful than the previous year's Lexus, fuel economy had actually improved by 10 per cent. What's more, the additional effect of front wheel regeneration meant that front brake wear was less than half that initially expected.

THS-R: developments for Le Mans

As significant as it was to win the Tokachi 24-hour race in a hybrid vehicle, the ripples of this achievement had not spread further than the domestic market. Toyota needed a bigger, more international audience to appreciate its efforts in hybrid racing technology.

The challenge was therefore set to develop a purpose-built car to make a return to an international endurance championship, and of particular importance in terms of worldwide publicity, compete once again in the 24 Hours of Le Mans. But in order to do so competitively, the weight of the hybrid system had to be reduced. Not just slimmed down but cropped savagely from around 600kg to just 100kg!

The technologies to achieve this simply didn't exist at the time. So Toyota engineers went back to the drawing board, spending the years from 2008 to 2011 evolving the early but now race-proven THS-R system.

THS-R: 2012 Toyota TS030 Hybrid

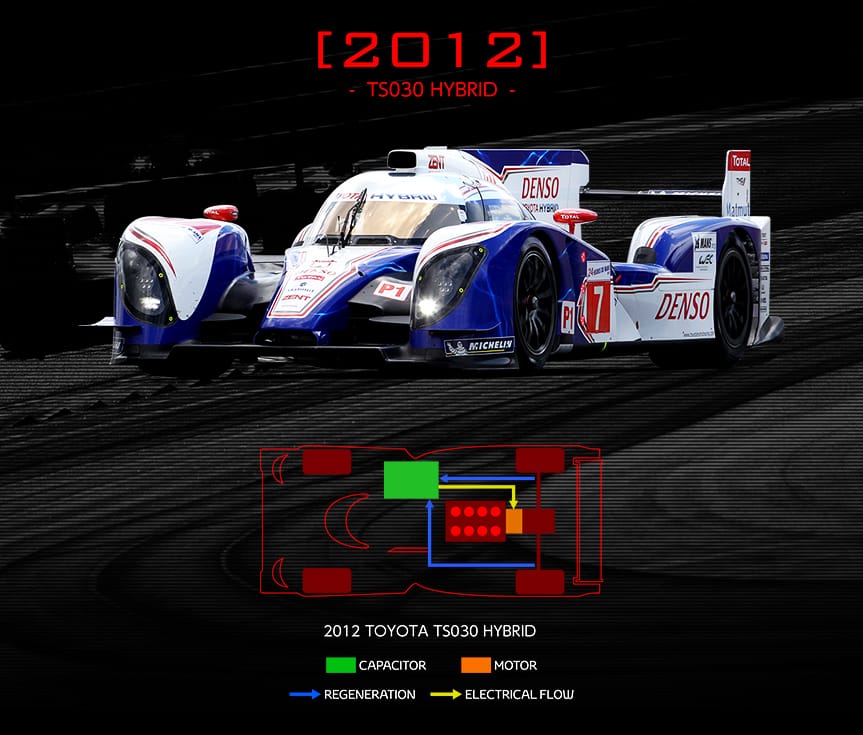

Toyota spent six years developing THS-R for top-level motorsport. The end result―the TS030 Hybrid―was the result of a combined effort between engineers at the Higashi-Fuji Technical Centre in Japan and the former Toyota F1 team operator in Germany, which built the car's carbon fibre chassis. It became the first petrol-electric hybrid vehicle entered in the inaugural FIA World Endurance Championship.

Leading the powertrain was an all-new 3.4-litre naturally aspirated V8 petrol engine. It was partnered by a powerful, double-layer super capacitor-based hybrid system co-developed by team partner Nisshinbo and housed in the cockpit.

During development of the TS030, MGUs were employed at the front and rear ends respectively. However, new LMP1 regulations for 2012 limited hybrid systems to recovering a maximum of 500kJ between braking zones and restricted deployment to only two wheels. This change halved Toyota's opportunity to recover and exploit brake force energy, leaving the Denso-made unit within the gearbox casing as the only MGU.

Nevertheless, a remarkable debut season produced three victories in six races as well as three pole positions and four fastest laps, highlighting the impressive performance of the TS030 Hybrid and its next-generation THS-R technology.

THS-R: 2013 Toyota TS030 Hybrid

The 2013 Toyota TS030 Hybrid inherited the basic specification and architecture of the 2012 model, albeit with improved component management and reliability. The super capacitor-based THS-R was now tuned to deliver 300bhp of boost in addition to the 530bhp generated by the 3.4-litre V8 petrol engine. But while power was up, the key advantage in terms of endurance racing was a significant improvement in fuel efficiency.

Having suddenly lost the option of a second MGU just before the start of the 2012 season, development time ahead of the 2013 season was also put to good use adapting the chassis to make better use of frontal space. This included redesigned front suspension and subtle aerodynamic refinements.

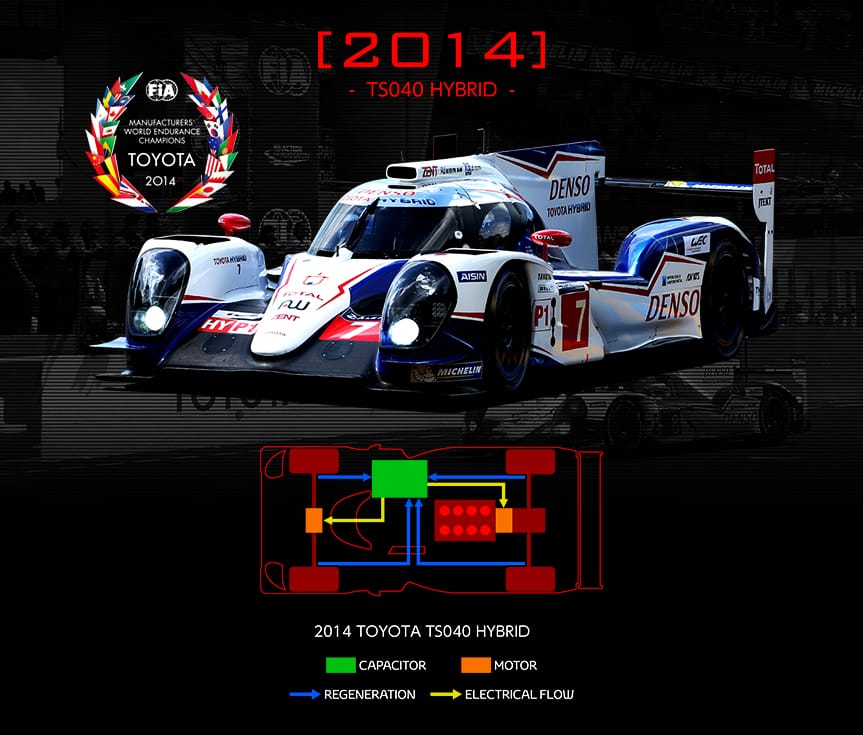

THS-R: 2014 Toyota TS040 Hybrid

Revised WEC technical regulations for the 2014 season put greater emphasis on fuel economy, requiring teams to use 25 per cent less fuel. But the revisions also allowed up to eight megajoules of electrical energy to be released and the possibility of installing MGUs on each axle to improve performance.

While the thought of deploying eight megajoules was no doubt tempting, it would have meant carrying extra weight in terms of hardware. Instead, Toyota engineers decided to evolve the THS-R set-up to carefully balance two MGUs (restoring the Aisin AW unit to the front axle as originally intended) with a more modest six megajoule maximum output. This was in addition to enhanced brake recovery potential and power from an increased capacity 3.7-litre V8 engine.

Combining the 480bhp output of the new twin-motor, super capacitor-based hybrid system with the 520bhp of the new engine gave the TS040 Hybrid a total output in excess of 1,000bhp, not to mention four-wheel drive grip and stability.

After only three years in the WEC, ever-improving THS-R technology at the heart of the TS040 Hybrid helped it secure the manufacturer championship―a first for a Japanese manufacturer―as well as the drivers championship in the 2014 season.

THS-R: 2015 Toyota TS040 Hybrid

For the 2015 WEC season the title-winning TS040 Hybrid underwent an evolutionary change.

In terms of headline figures, the car retained its 1,000bhp output and six megajoule hybrid energy allowance. But beneath the skin around 80 per cent of its parts had been redesigned to improve performance and reliability and to optimise weight. Two aerodynamic packages were also developed to cope with the differing demands of WEC circuits.

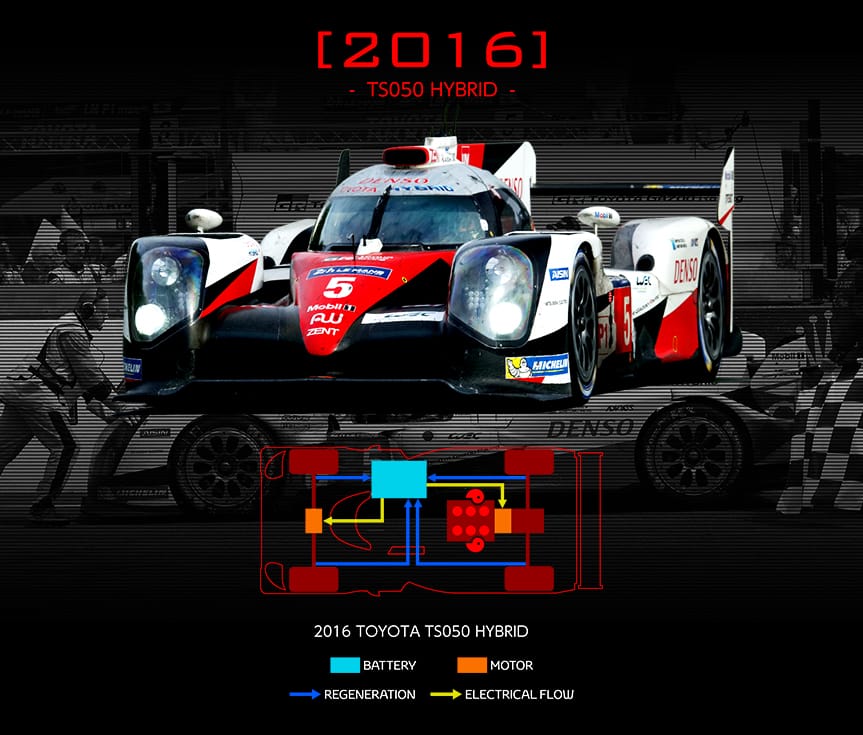

THS-R: 2016 Toyota TS050 Hybrid

The new TS050 Hybrid displays the most significant development in the THS-R concept since Toyota joined the championship in 2012.

The new-generation petrol engine, again engineered by the Motor Sport Unit Development Division at Toyota's Higashi-Fuji Technical Centre in Japan, is a downsized 2.4-litre V6 with direct injection. But it is also boosted with twin turbochargers and a powerful eight megajoule hybrid system running from a high-powered lithium-ion battery in place of the previous super capacitor set-up.

As before, an MGU is provided for each axle, the front system relocated for better under-floor airflow and to deliver electric four-wheel drive to assist the dual-powered rear axle.

This new THS-R concept has brought different cooling and packaging demands, including an updated transmission to handle the increase in torque from the turbo engine. Combined with a new aerodynamic concept, this means virtually every part of the TS050 Hybrid chassis has been redesigned.

Learn more about TOYOTA GAZOO Racing

http://toyotagazooracing.com/