01

STAMPING

Making Parts That Form the Basis

of the Car Body

from Large Steel Plates

-

Preparing

-

Carrying and

Stretching -

Punching

-

Stamping

-

Arranging

SCROLL

More than a Dozen Steel Plate Types

are Used per Car

Cars use different steel plates for different parts.

Let's Explore

Why are 20 different types of steel plates needed?

Exploring Stamping

Both Hard and

Soft Steel Plates

are Required

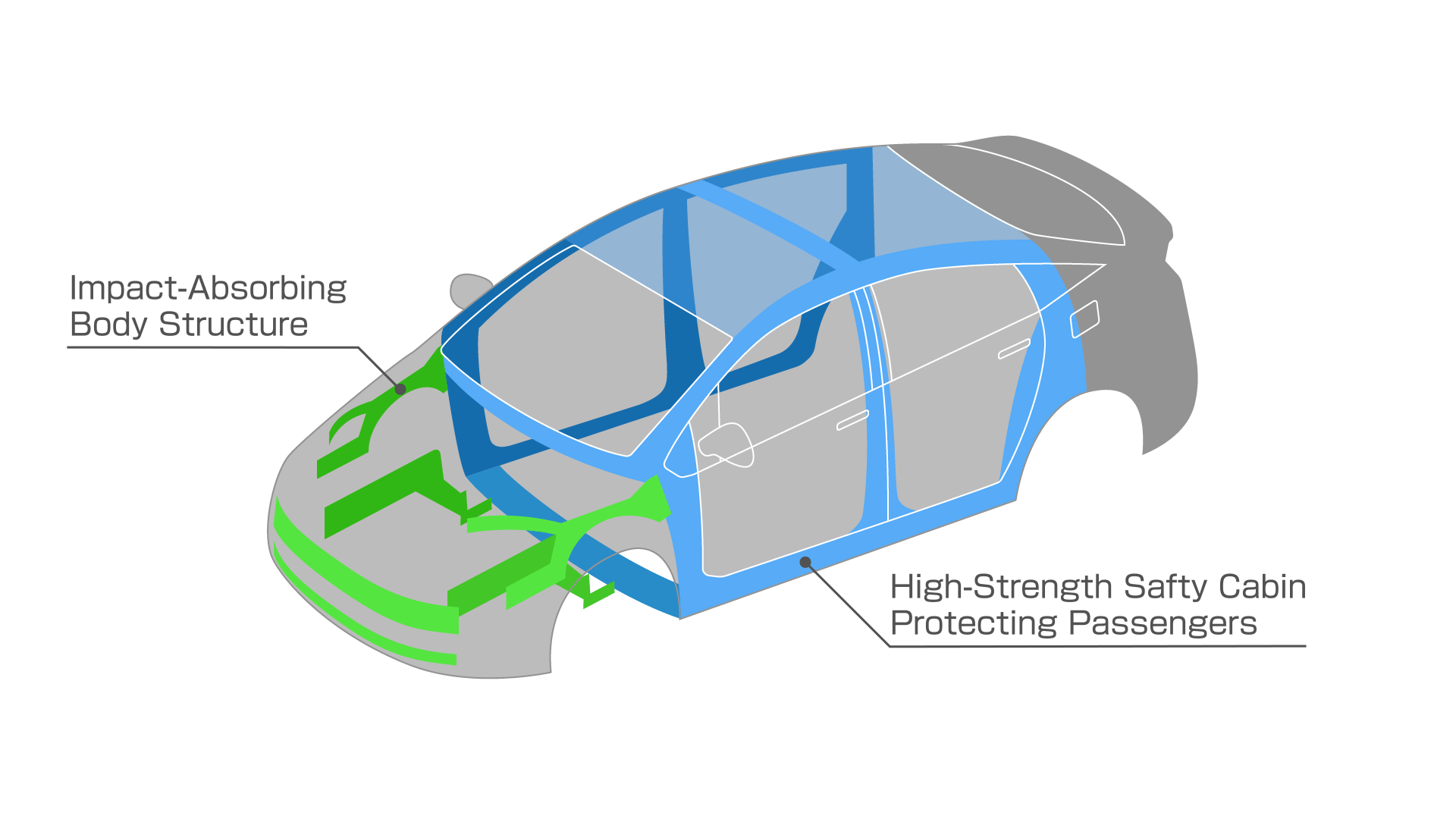

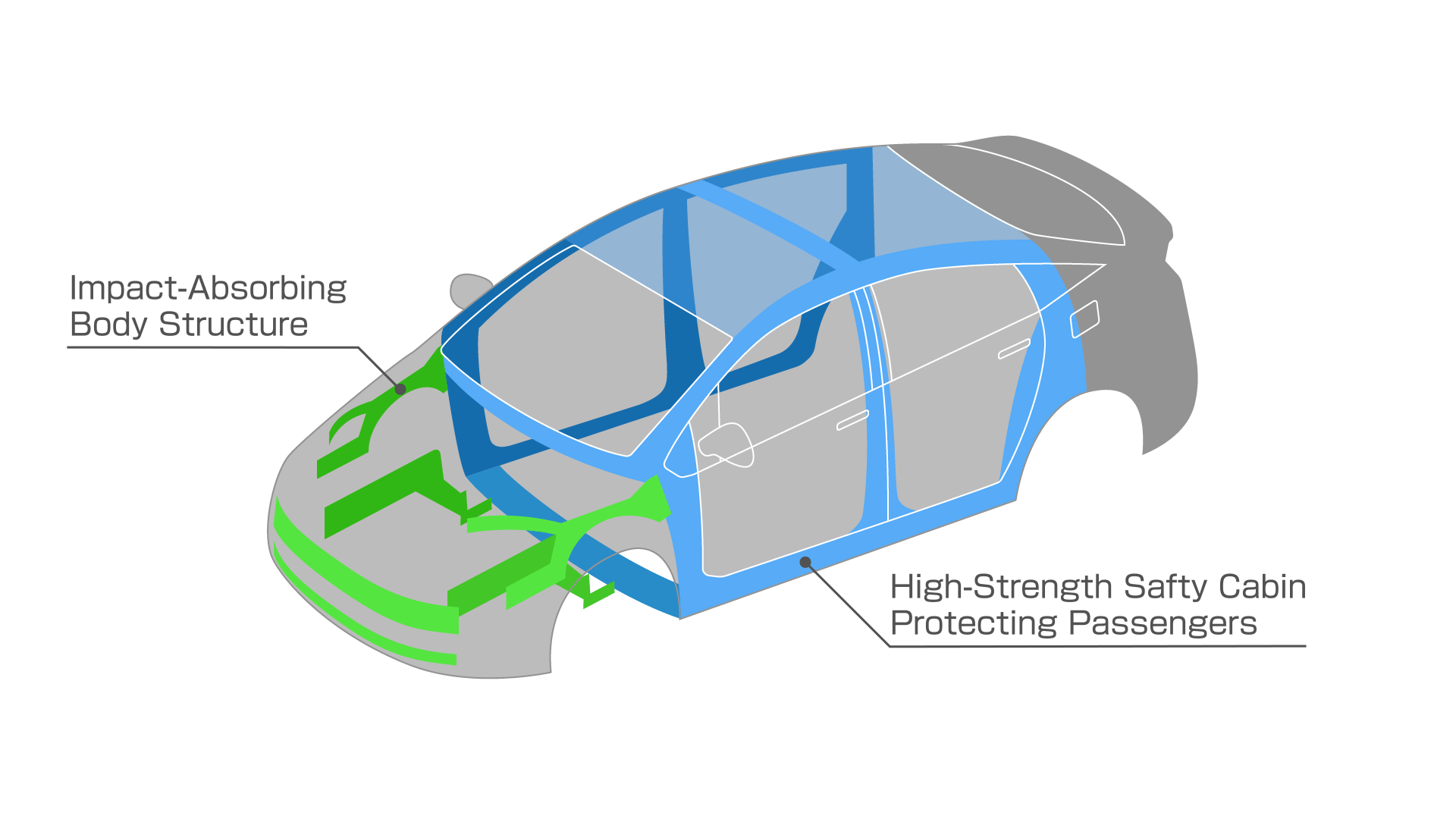

Properties required for steel plates vary based on location. For example, to protect occupants during a collision, hard materials are used in the cabin, while easily deformable materials are used in other areas to absorb impact.

SCROLL

Exploring Stamping

Both Hard and

Soft Steel Plates

are Required

Properties required for steel plates vary based on location. For example, to protect occupants during a collision, hard materials are used in the cabin, while easily deformable materials are used in other areas to absorb impact.

SCROLL

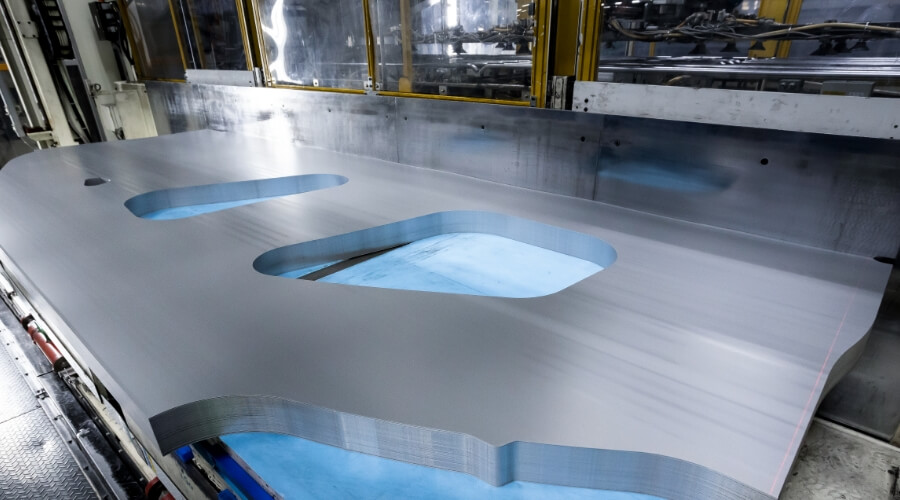

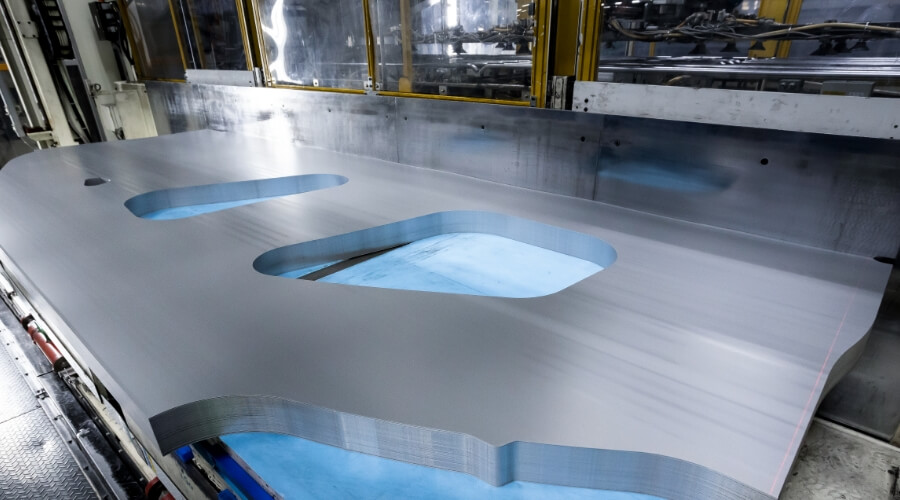

One Roll is Enough to Make

About 300 Cars

Once straightened, the longest roll is about2.5 kilometers long.

SCROLL

Utilizing All Parts

Without Waste

Steel plates are cut and punched into part shapes at the same time.

Excess parts are used for other parts or reused by steel companies.

Let's Explore

All left over pieces are fully utilized

Exploring Stamping

Fully Utilizing

Left Over Pieces

Openings are created where the doors will be attached.

The material removed to create space for the doors is reused as parts inside the trunk.

SCROLL

Exploring Stamping

Fully Utilizing

Left Over Pieces

Openings are created where the doors will be attached.The material removed to create space for the doors is reused as parts inside the trunk.

SCROLL

Creating Elaborate Shapes Through a Four Step Stamping Process

Each step takes just 3 seconds, applying 1,600 tons of pressure vertically.

1st Step

Steel plates are pressed into a die to form a three-dimensional shape.

2nd Step

Excess plates are cut off.

3rd Step

Plates are bent and drilled.

4th Step

Then remaining parts are bent and drilled to complete the pressed product.

Let's Explore

What helps create a beautiful shape?

Let's Explore

What helps create a beautiful shape?

Exploring Stamping

Precision Molding to

1/1000 mm Threshold

It is through the stamping machine die that beautiful car designs can be brought to life.

Commitment to Craftsmanship High-Precision Die Making

Feeling the Slightest Difference

Through Fingertips

Adjusting dies to achieve beautiful body lines requires delicate manual work in 1/1000-millimeter increments. What kind of craftsmanship cannot be imitated by machines?

Commitment to Craftsmanship The Beautiful Form of the Lexus IS

New Methods

and Passion

Make the Impossible Possible

Our goal is to realize the body lines of the Lexus IS exactly as the designer intended. With that passion, a new stamping method was born.

SCROLL

Commitment to Craftsmanship

High-Precision Die Making

Feeling the slightest difference

through fingertips

Adjusting dies to achieve beautiful body lines requires delicate manual work in 1/1000-millimeter increments. What kind of craftsmanship cannot be imitated by machines?

Commitment to Craftsmanship

The Beautiful Form of the Lexus IS

New Methods and Passion

Make the Impossible Possible

Our goal is to realize the body lines of the LEXUS IS exactly as the designer intended.

Exploring Stamping

Precision Molding to

1/1000mm Threshold

It is through the stamping machine mold that beautiful car designs can be brought to life.

SCROLL

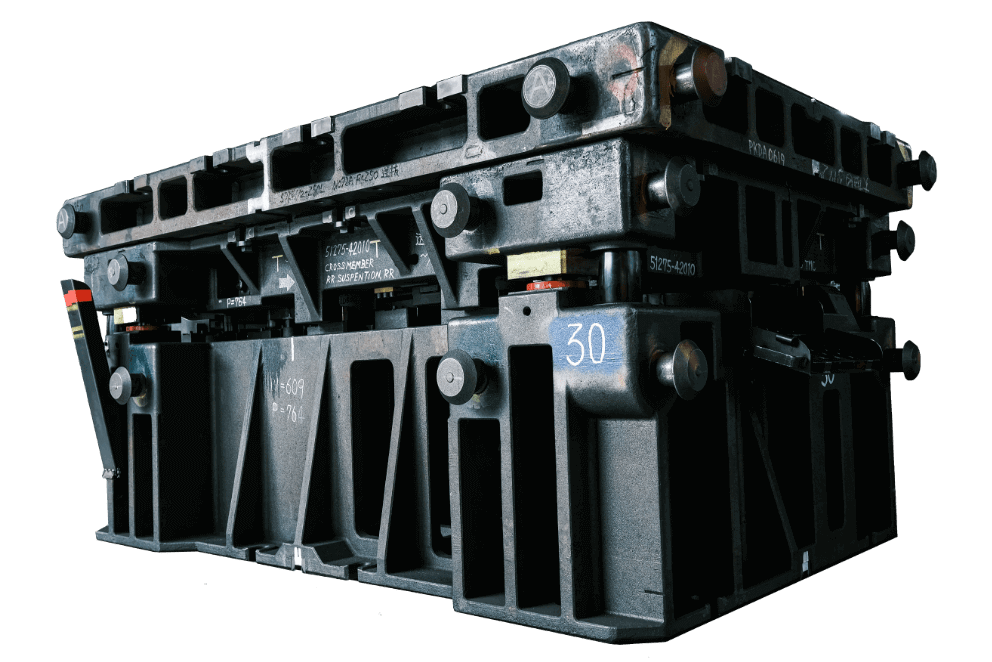

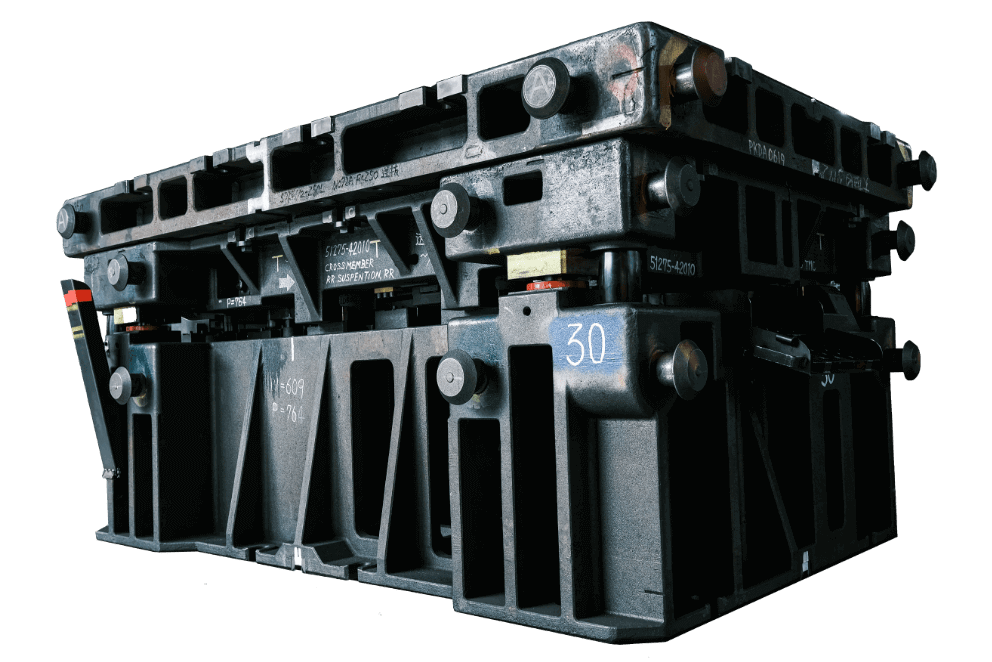

Mixed Model Production

Starts Here

Toyota can manufacture various types of vehicles on one production line. This is called "Mixed Model Production." The pressed parts are rearranged in the order in which they are used and picked up for the next process.

02

WELDING