02

WELDING

Bringing Together

Various Parts

to Form a Car

-

Assembling

the Car Body -

Performing

Additional Welding -

Attaching Doors

and Various Parts -

Inspecting

the Car Body

SCROLL

Forming a Car

Through a Variety of

Stamped Parts

The floor, sides and ceiling are then assembled, and as many as4,000places are welded to form the car.

SCROLL

The Decisive Factor

in Increasing Strength

Special robots weld more than

500 additional locations to strengthen the body.

Exploring Welding

Toyota uses three major welding methods

Exploring Welding

This method uses electric current to fuse together metal parts.

Spot Welding

This process is used to weld two or more steel plates by applying pressure, and heat from an electric current focused on a particular "spot." Most welding in automobile production utilizes this method.

This method uses electricity to generate heat to join steel plates.

Arc Welding

This welding process utilizes an electric arc between a metal stick ("electrode") and the base material to melt the metals at the point of contact.

It is used for areas where spot welding is difficult to perform (because it cannot be clamped by electrodes).

This welding method is for high-speed high-precision joining.

Laser Welding

This is a method of joining steel plates by melting them with a laser.

It has excellent joint strength and is used to join steel plates of different thicknesses and materials.

Commitment to Craftsmanship

The Evolution of Welding

Advancing Laser Technology to

Further Increase Vehicle Strength

Laser welding allows for the joining of more areas at higher speeds.

SCROLL

SCROLL

Commitment to Craftsmanship The Evolution of Welding

Advancing Laser Technology to

Further Increase Vehicle Strength

Laser welding allows for the joining of more areas at higher speeds. We have taken advantage of this feature to bring forward even more advanced welding technology. Let us introduce a few key points.

Beautiful Styling

is Born

from Precision

The doors, hood, and trunk lid, among additional parts are attached to the assembled body.

Let’s Explore

What is done to the car to help with precision?

Exploring Welding

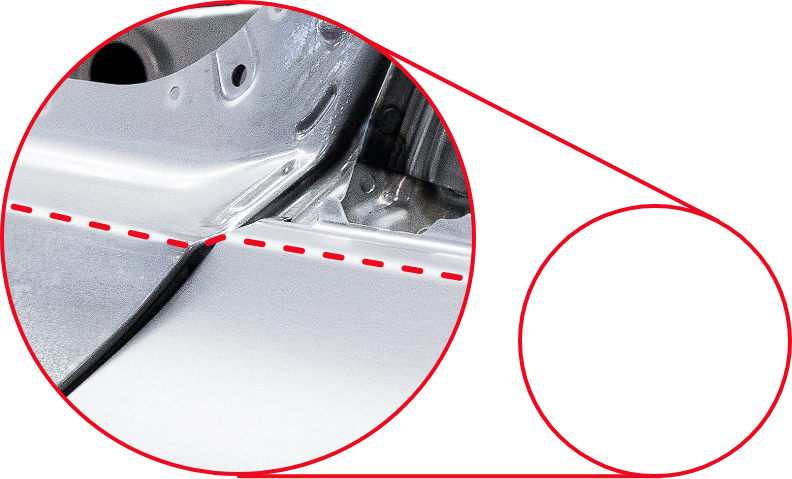

Doors are

Intentionally

Displaced

When the window glass and other components are attached to the doors in subsequent assembly process, the additional weight lowers the doors back into alignment.

SCROLL

Point of WELDING

Doors are

Intentionally

Displaced

When the window glass and other components are attached to the doors in subsequent assembly process, the additional weight lowers the doors back into alignment.

SCROLL

Not Passing

On Any Defects

If scratches are found after painting, it is difficult to determine whether the cause was the welding process or the painting process, and because of this no immediate countermeasures can be taken.That is why we actively inspect each process. In this way, Toyota places importance on "building quality into each process," which is called Jikotei-kanketsu (self-completion).

03

PAINTING