Nov. 08, 2018

Toyota Develops World's First General-purpose Hydrogen Burner for Industrial UseNewly developed structures reduce NOx emissions to below natural gas burner levels, zero CO2 emissions from combustion

Toyota City, Japan, November 8, 2018―Toyota Motor Corporation (Toyota) has developed the world's first1 general-purpose hydrogen burner for industrial use in collaboration with Chugai Ro Co., Ltd. The burner will be used from today at the forging line in Toyota's Honsha Plant.

In conventional hydrogen burners, hydrogen reacts rapidly with oxygen, leading to a high flame temperature and environmentally hazardous NOx emissions. On account of this, the practical use of hydrogen burners has proved challenging. The newly developed burners incorporate two new structures that enable hydrogen to combust more slowly. The new burners also have zero CO2 emissions and greatly reduced NOx emissions2, resulting in outstanding environmental performance.

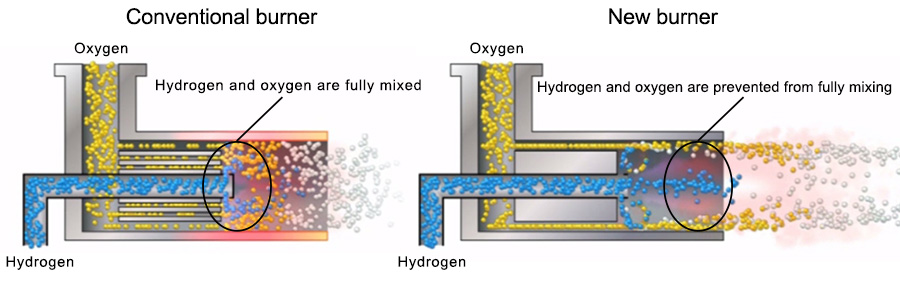

- Preventing hydrogen and oxygen from mixing completely

If hydrogen and oxygen are in a fully mixed state when ignited, the mixture burns violently with a high flame temperature. In the newly developed burner, hydrogen and oxygen flow side-by-side and are ignited without being fully mixed, leading to slower combustion and a lower flame temperature.

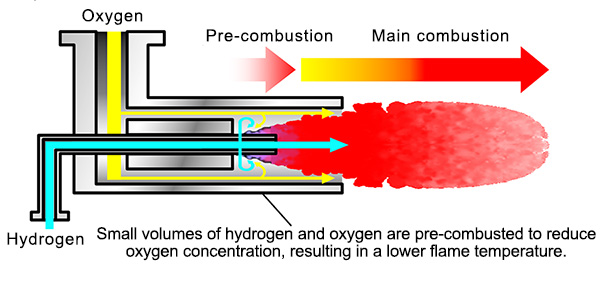

- Lowering oxygen concentration inside the furnace

If the fuel mixture contains a high concentration of oxygen at the time of ignition, combustion is violent with a high flame temperature. To prevent this, small holes are opened in the pipes that supply hydrogen to the burner, enabling small volumes of hydrogen and oxygen to pre-combust. Oxygen concentrations are consequently reduced to an optimal 19-percent level for main combustion, resulting in a lower flame temperature.

To achieve the targets set out in its Plant Zero CO2 Emissions Challenge, which forms part of the Toyota Environmental Challenge 2050, Toyota is implementing innovative technologies and everyday kaizen (continuous improvement) activities. Toyota also aims to use energy in its plants that comes from renewable sources, including hydrogen energy.

The new technologies announced today will enable 1,000 large-scale natural gas burners to be replaced by hydrogen burners at our plants across Japan. Conventional technology is responsible for significant volumes of CO2 emissions; to realize its Plant Zero CO2 Emissions Challenge, Toyota is planning to install hydrogen burners gradually at its other plants, and other companies in the Toyota Group are also considering installation.

Going forward, Toyota seeks to realize a hydrogen-powered society and reduce its industrial carbon footprint by promoting industrial hydrogen use and by contributing to increased demand for hydrogen.

*1As of November 8, 2018, according to Toyota Motor Corporation

*2Lower than natural gas burners of an equivalent scale