Mar. 24, 2025

Researching Better Processes Using the Process Simulator GEN-VIR®Improving the Accuracy of Worker Muscle Fatigue Prediction Technology: Construction Kaizen Part 5

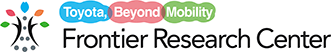

At Toyota Motor Corporation's Frontier Research Center (hereinafter referred to as Toyota), we are seeking solutions to the labor shortages and aging issues faced not only in the automotive industry but also in the construction sector as we transform into a mobility company. As part of this effort, we have been collaborating with Obayashi Corporation (hereinafter referred to as Obayashi) and the Toyota Central R&D Labs., Inc. (hereinafter referred to as TCRDL) to develop the process simulator "GEN-VIR®*1."*2-4 This simulator aims to not only streamline work processes but also predict the physical burden (muscle fatigue) on workers, with the goal of creating better work processes. In this discussion, we will talk about improvements in muscle fatigue prediction technology and efforts toward on-site improvements.

- Does GEN-VIR allow for the consideration of not only work efficiency but also muscle fatigue?

- Adachi

- Yes. By simulating work processes, we can output a work time log showing when workers are working and when they are waiting. When we add data of work posture and external forces acting on the body to this log, we can calculate the required muscle strength for each task and predict the overall muscle fatigue (or residual capacity) that occurs across the entire process. I will discuss the acquisition of work posture data, while Mr. Osada from TCRDL will introduce the technology for calculating muscle strength and muscle fatigue.

-

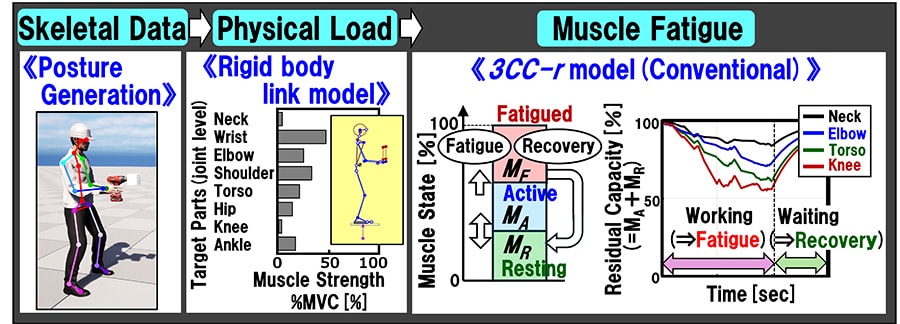

- Figure 1 Overview of the calculation of work efficiency and muscle fatigue in GEN-VIR

- What challenges did you face in acquiring work posture data?

- Adachi

- Until now, we obtained several work postures through motion capture and selected similar posture data regardless of the work content to perform muscle strength calculations. However, since postures change depending on the work position, using only the work postures that we captured was insufficient for accurate muscle strength calculations. On the other hand, capturing every possible work posture through motion capture was not practical. Therefore, we considered that if postures change according to the work position, we could generate work postures in a 3D simulation based on the work position and conducted research on posture generation.

- How did you specifically proceed with this?

- Adachi

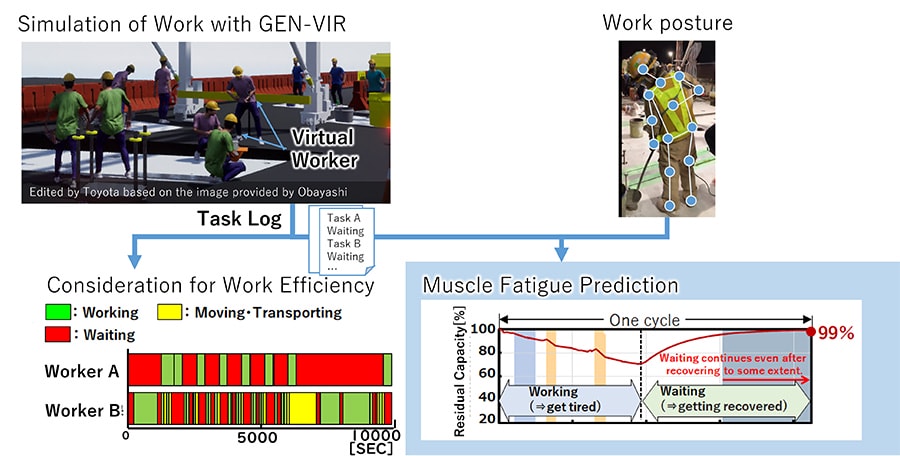

- First, we observed past work videos to investigate what postures workers adopt during various tasks. We found that workers rarely adopt a half-squat position and primarily work in either a standing or crouching posture. For example, when observing the task of driving bolts into a wall from head height downward, we noted that when driving bolts at a height slightly below the pelvis, workers would not bend down into a squat but would instead crouch momentarily and reach up to drive in the bolt. This indicated that workers choose crouching postures while considering work efficiency and physical burden. We also confirmed that while postures vary by task type, they can be somewhat classified by work direction.

-

- Figure 2 Insights gained from observing work videos regarding work posture

- Adachi

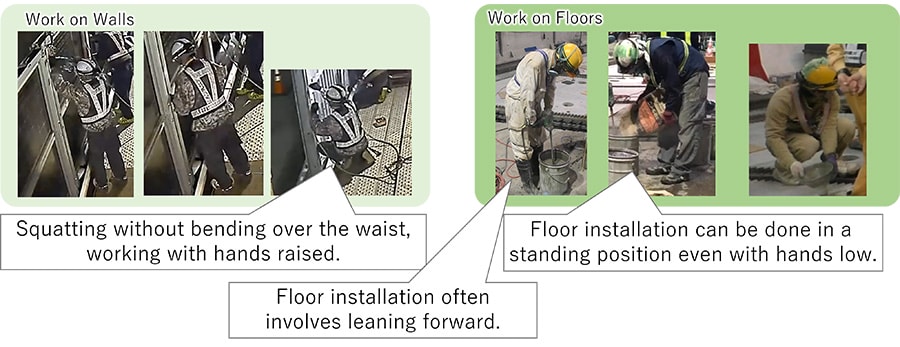

- Next, we obtained work postures through motion capture and analyzed the movements of each joint. As a result, we discovered a correlation between hand height and pelvis height, which we formalized.

-

- Figure 3 Obtaining work posture data through motion capture and analysis results

- Adachi

- By combining the relationship equations into an algorithm, we were able to automatically generate the entire body posture when a virtual worker adjusts the position of tools according to the work position. Moreover, since the joint angles of the virtual worker can be easily obtained in the simulation, we can acquire highly accurate joint angle data for work postures simply by conducting simulations. You can see how various work postures are generated virtually in the following video.

- Video 1 Work posture generation algorithm

- So, how do you predict muscle fatigue from work postures and the external forces acting on the body?

- Osada

- First, we recreate work postures using a simplified human model that connects each joint with rigid links, and based on the external force values, we determine the necessary muscle strength ratio (%MVC*5) to maintain that posture using a commercially available static strength prediction program (Figure 4, center). Next, this muscle strength ratio serves as a command value to simulate, by using muscle fatigue model*6*7, whether the muscles are in an active, fatigued, or resting state, allowing us to calculate how the residual capacity (the amount of muscle in an active or resting state) changes over time (Figure 4, right).

-

- Figure 4 Workload Analysis Framework

- I see. However, in actual construction sites, there are people with various physiques working, right?

- Osada

- That's correct. Muscle strength varies with physique. The static strength prediction program we use to determine muscle strength ratio is based on a database of Western individuals, so applying it directly to individuals of different physiques, such as Japanese, was not feasible. Therefore, we systematically organized past experimental data where muscle strength was measured to make it applicable to Japanese workers. Additionally, we can now reflect attributes such as age, gender, weight, and whether the individual is a general person or a construction worker*8. As the aging of construction workers and the entry of women into the field accelerate, we hope this technology will be utilized to create a more comfortable workplace through detailed analysis and responses.

- The key point is that you have adapted to the diversity of workers. If there are other points of improvement, please let us know.

- Osada

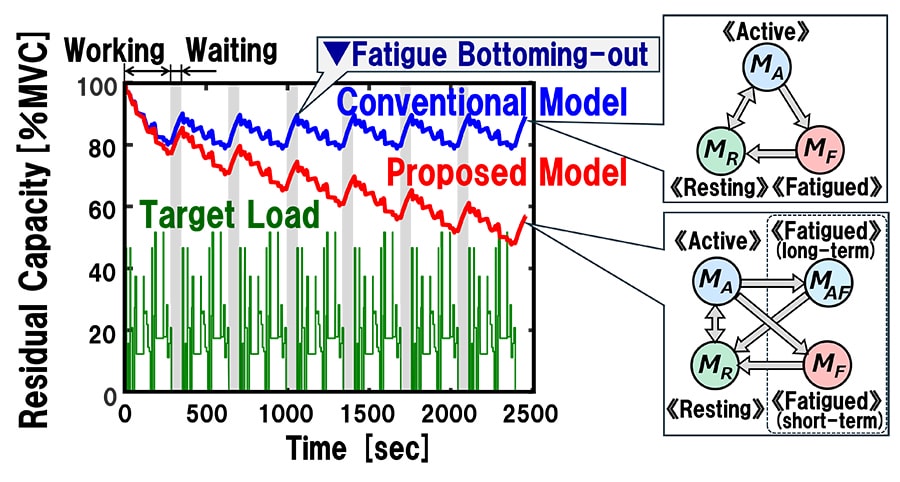

- Actually, the conventional muscle fatigue model had a problem where the residual capacity bottomed out under certain conditions.

- So, the simulation results would suggest that workers can continue working indefinitely without fatigue?

- Osada

- Yes. In reality, there are three types of muscle: those that contract slowly but are resistant to fatigue, those that contract quickly but fatigue easily, and those that contract quickly and are resistant to fatigue. The conventional muscle fatigue model we used so far treated these types as one, so optimizing parameters for short-term repetitive tasks did not apply well to long-term repetitive tasks. While models considering the three types of muscles have been proposed, they became impractical due to an excessive number of parameters. Therefore, we proposed a new muscle fatigue model*9*10 that simply divides the "fatigued" state of the muscle into short-term and long-term aspects, making it applicable to actual work processes (Figure 5).

-

- Figure 5 Analysis example of actual work process using conventional and proposed models

- Please tell us about your efforts on actual construction sites.

- Adachi

- Yes, we utilized the improved muscle fatigue prediction technology to examine improvements in the Tomei Expressway Renewal Project*11. During the mortar casting*12 process, we found that muscle fatigue significantly increased for workers kneading mortar, leading us to consider introducing machinery. We also compared how changes in work methods would affect work efficiency using GEN-VIR. For more details, please visit Obayashi's official website (Japanese only).

- What are your future prospects?

- Osada

- One of the challenges at outdoor construction sites is the hot environment. We aim to improve our models to accommodate work in hot conditions.

- Adachi

- I believe this technology can also be applied to other Obayashi projects and fields outside of civil engineering. We will continue to work hard to accumulate achievements in more sites and develop technology that enables better improvement discussions.

Authors

Hiroshi Osada

Joined Toyota Central R&D Labs., Inc. in 1987. After working in heat transfer and energy conversion technology development and safety and disaster management, he is currently engaged in work burden analysis technology.

Nagisa Adachi

Joined Toyota Motor Corporation in 2013. Previously responsible for product evaluation of partner robots. In this project, mainly responsible for posture generation technology for virtual workers within simulations.

-

- Osada (Right) and Adachi

References

| *1 | A process simulator jointly developed by Toyota Motor Corporation and Obayashi. Based on Toyota's concept of "genba-genbutsu," it aims to improve work processes in a virtual environment and evolve to create human-centered processes. GEN-VIR is a coined term combining "GEN," the Japanese reading for "on-site" and the first three letters of "virtual." It is a registered trademark of Toyota Motor Corporation. |

|---|---|

| *2 | Using Simulation to Improve Conditions for Construction Workers - Reducing Construction Time through Kaizen PART 2 - |

| *3 | Developing a Construction Simulator That Can Be Used by Anyone for Any Process - Construction Kaizen to Improve Conditions for More Construction Workers PART 3 - |

| *4 | Making a Better Ever Processes! Virtual On-site Replication with Process Simulator Risk Visualization and Process Optimization |

| *5 | The ratio of load to the maximum muscle strength that muscles can exert. MVC stands for Maximal Voluntary Contraction. |

| *6 | 3CC-r muscle fatigue model (Three-compartment controller muscle fatigue model) |

| *7 | Looft, J.M. et al., "Modification of a three-compartment muscle fatigue model to predict peak torque decline during intermittent tasks," J. Biomech., Vol.77 (2018), pp.16-25. |

| *8 | Hiroshi Osada et al., "Workload Analysis in Infrastructure Construction Work (1st Report) -Chronological Muscle Fatigue Analysis Reflecting Worker Characteristics-", The Japanese Journal of Ergonomics, Vol.59, Supplement (2023), O1A6-01. (Japanese only) |

| *9 | 4CC-r muscle fatigue model (Four-compartment controller muscle fatigue model) |

| *10 | Mitsuyoshi Kawakami et al., "Workload Analysis in Infrastructure Construction Work (2nd Report) -Improvement Proposal for the Three-Compartment Controller (3CC-r) Muscle Fatigue Model-", The Japanese Journal of Ergonomics, Vol.59, Supplement (2023), O1A6-02. (Japanese only) |

| *11 | Tomei Expressway Renewal Project (Tomei Expressway Tamagawa Bridge)

|

| *12 | The process of casting mortar (a construction material made by kneading sand, cement, and water) into molds. |

Contact Information (about this article)

- Frontier Research Center

- frc_pr@mail.toyota.co.jp