Mar. 24, 2023

Developing a Construction Simulator That Can Be Used by Anyone for Any Process- Construction Kaizen to Improve Conditions for More Construction Workers PART 3 -

Toyota Motor Corporation (Toyota)'s Frontier Research Center has been working to develop a Construction Simulator to improve conditions for construction workers as part of its research into innovative infrastructure technologies.

The Kaizen of work processes using the simulator in 2021 produced significant results, including a halving of work hours without changing the load on workers. On the other hand, the larger the scale of a construction, the longer it takes to create the simulator. In the first place, it was difficult to create the simulator without mastering coding techniques. Therefore, in 2022, we worked with Obayashi Corporation (Obayashi) to evolve the simulator into a tool that is easy to use and can be utilized in large and complex operations. In this article, we will introduce the details of our efforts and key points of the development with a development member, Nagisa Adachi.

-

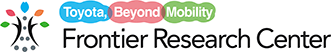

- Image 1 Conceptual image of Tomei Expressway Tamagawa Bridge floor slab replacement (above, overhead view of the construction; below, view of the construction from the expressway)

What are the Difficulties in Simulating Large-scale Constructions?

―You mentioned that this is a larger scale construction. What type of construction did you utilize the simulator for? How did the construction differ from the previous work?

- Adachi

- The construction we worked on this time was the replacement of floor slabs at the Tomei Expressway Tamagawa Bridge within the Tomei Expressway Renewal Work1. Among them, the simulator was utilized for the floor slab joining process2. This is a process that involves more workers and coordination of more tasks. The first difference from the previous construction work is the number of workers. Last time, there were two teams with a total of four workers; this time there were four teams with a total of 12 workers, three times as many as last time. The second difference is that the coordination of tasks was more varied than last time. Previously, each team was independent in both task scope and work spaces, so workers did not join another team to work together or in the same space. This time, however, several teams are working in a single area, where some tasks are performed independently by each team while others are performed by several teams working together. (Image 2)

-

- Image 2 Differences between previous and this construction

―Wouldn't the coding of the simulator be very complex when utilizing it for such construction where 12 people are working in coordination with each other? Did it take a long time to create the simulator?

- Adachi

- Yes, that's right. When we create the simulator, we code the behavior of each worker, so if the number of workers triples, it will take three times as long to create the simulator by simple calculation. It took about 1.5 months to create the simulator for the previous construction, so this time, it will take 4.5 months. In addition, this time, it is necessary to code conditional branching that depends on the progress of the work and the status of the worker in charge, which also takes time to create.

―It looks like it will take more than six months to create the simulator (laughs).

- Adachi

- As the simulator is essentially a tool for Kaizen of the work, it is necessary to go through the Kaizen cycle over and over again. Once the simulator has been created, we examine the Kaizen plan for the work, modify the simulator based on the results of that examination, and then check the work again. Therefore, we found that for better Kaizen activities, we need to review the simulator coding method to make it easier to create the simulator in a shorter time.

Evolving simulator creation methods for better Kaizen activities

―So you are saying that Kaizen is applied not only to the work but also to the simulator, which is the tool for Kaizen. How did you actually evolve the simulator?

- Adachi

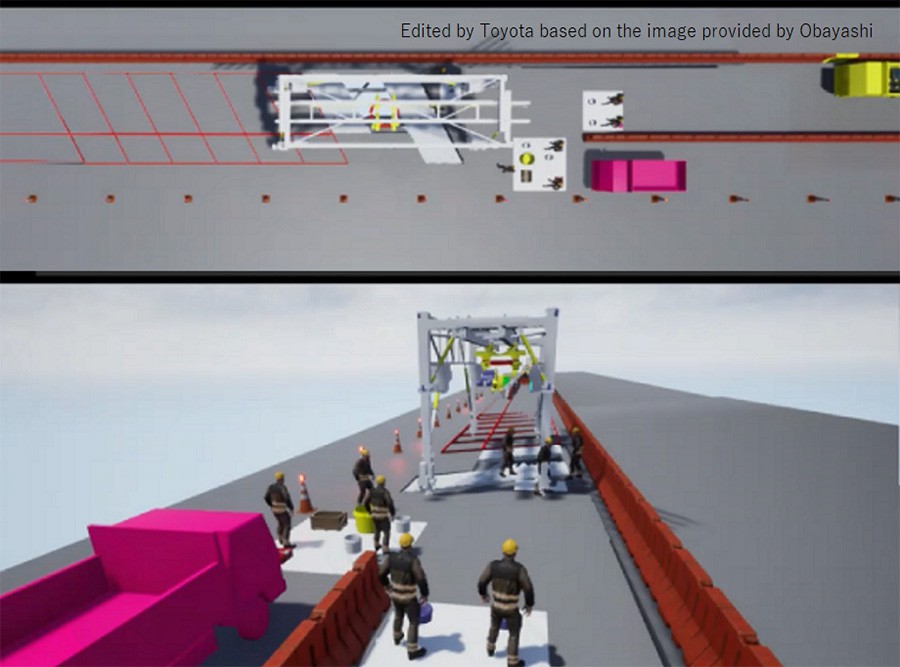

- One of Toyota's Kaizen concepts is the complete elimination of all waste. We considered what constitutes waste in simulator creation. In the past, when coding tasks, we coded each of the accompanying states of moving to the next work location and transitioning to the standby state when the task has been completed. (Image 3) However, what we want to focus on when implementing Kaizen of the work should be work-related issues such as time and order of tasks. We then considered whether the ancillary items such as coding move and wait states could be combined into the code for each task.

-

- Image 3 Example of coding a sample task using the previous method

First, we have introduced a system that automatically enters the standby state after determining whether there is a next task to be done and whether it can be started. Next, regarding moving of the worker, information such as the work position and the direction of the worker required for each task is different and thus could not be easily consolidated. Therefore, we decided on a two-step method. First, we pre-registered the work position and the direction of the worker for each task, and then coded the order of the tasks.

―I see. So you registered the work position and the direction of the worker in advance of coding the tasks. But with so many tasks, was it difficult to register them in advance?

- Adachi

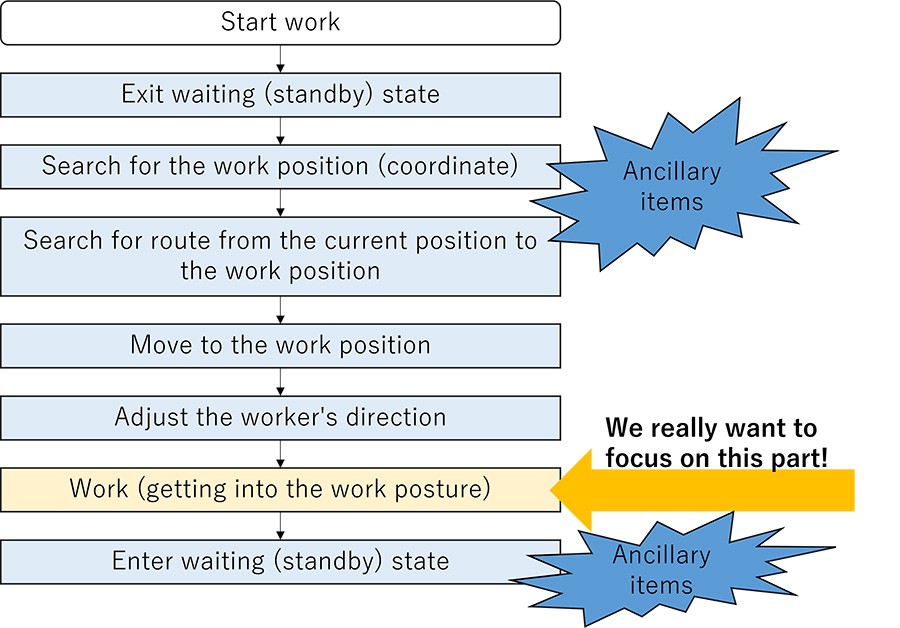

- Yes, so we devised the user interface (UI) to make pre-registration easy. As you can see in Image 4, the work point can be dragged with the mouse in the 3DCG work area. The position where the work point is placed is the work position (coordinate) and its direction is the direction of the worker. Other items such as working posture can be selected from a pull-down menu. This allows registration to be carried out intuitively by those unfamiliar with coding.

―It certainly seems intuitive to use.

- Adachi

- Separating the coding of tasks into the registration of work information and the order of tasks also facilitated the modification of the simulator. For example, if the time for Task A was shortened as a result of Kaizen, we only need to edit the work information of Task A to reflect the change in all Task A found in the order of tasks.

-

- Image 4 User interface to register the work information developed this time;

information can be registered intuitively using 3DCG and item fields

―Speaking of which, one of the purposes of evolving the simulator this time was to change it into a tool that anyone can use. Have you achieved that?

- Adachi

- Yes. In fact, this time, Toyota focused on the development of the simulator's functions, while Obayashi members who know the civil engineering site well were in charge of creating the simulator and the Kaizen of on-site work. This was the first time that a simulator under development was created by someone other than the developer, Toyota. However, by giving lectures on how to use the simulator at the workshop, Obayashi members were able to learn how to create the simulator in a short period of time. The intuitive UI was also effective. After learning, Obayashi sometimes made suggestions to improve the simulator's UI from the perspective of a process planner.

―How long did it take Obayashi to create the simulator?

- Adachi

- The simulator for this construction work was ultimately prepared in just two weeks. As a result, we were able to start studying the Kaizen plan for the construction work, which was the original purpose.

―Two weeks! It was initially estimated to take about six months to create the simulator, so that's very fast. Did the greater speed of simulator creation affect the Kaizen activities?

- Adachi

- Yes. When we used the simulator to observe the construction work with site workers, they came up with ideas for Kaizen and we had a lively discussion. When multiple Kaizen proposals came from the site workers, we were also able to introduce several simulator results within a short period of time and select the better process among them. After seeing the progress of Kaizen activities through discussions, we confirmed that shortening the simulator creation time helped to promote Kaizen activities for the work. For more information on the results of the Kaizen of Obayashi's work, please see the press release from Obayashi (Japanese Only).

-

- Image 5 Discussing Kaizen proposals with site workers

Future Prospects

―Finally, can you tell us about the future prospects?

- Adachi

- With the evolution of the simulator coding method, we were able to implement Kaizen activities using the simulator even in large-scale construction work. We believe that Kaizen using the simulator can be applied not only to civil engineering sites but also to various other sites. We would like to evolve the simulator while utilizing it at various sites. We will continue to think about how the simulator should evolve to improve conditions for construction workers and develop this together with Obayashi and everyone on site.

-

- Image 6 Project members (the author is on the far right)

References

| *1 | Tomei Expressway Renewal Work (Tomei Expressway Tamagawa Bridge)

|

|---|---|

| *2 | Floor slab joining process The process where the following three tasks are undertaken while monitoring each other's progress to affix the newly installed floor slabs: (1) the joining floor slabs and main girders (casting ultra-fast hardening non-shrink mortar), (2) the installation of gap plates between floor slabs, and (3) the task of waterproofing. Mortar is a construction material, made by kneading cement with sand and water. |

Author

Nagisa Adachi

Assistant Manager, Infrastructure System Group No.2, R-Frontier Div., Frontier Research Center

She had previously been responsible for product evaluation of partner robots. For this project, she was mainly in charge of simulator design and evaluation.

Contact Information (about this article)

- Frontier Research Center

- xr-probot@mail.toyota.co.jp