Nov. 30, 2022

Tackling Methods for Elimination of Utility Poles in Readiness for the Future Electrified Mobility SocietyAiming for the realization of a safe, secure, environmentally friendly, and comfortable society

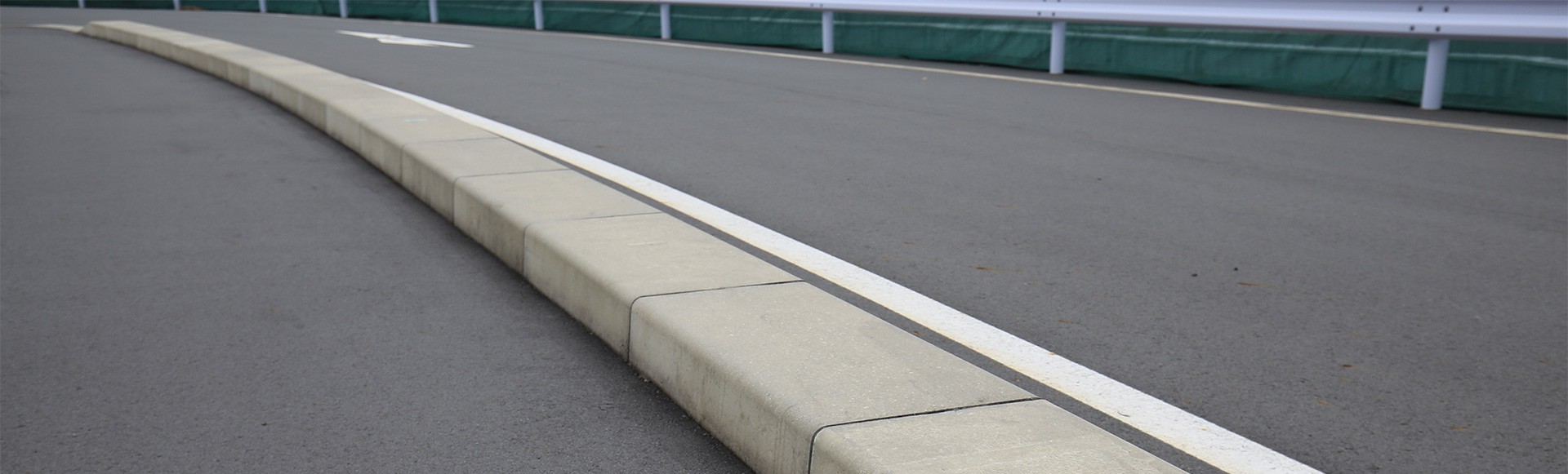

Toyota Frontier Research Center is conducting research and development for mobility infrastructure with an eye on the future arrival of autonomous vehicles and the further adoption of environmentally friendly electrified cars. Please see Image 1, which depicts one impression of the future mobility society. You may notice the large curbstones between the road and the sidewalks. In fact, they contain key infrastructure including power and communications lines. If power and communications lines are located alongside sidewalks in this way, we can efficiently install the battery charging stands, and high-speed wireless communication base stations, etc. essential to realize automated driving. We believe that this will help us to flexibly deal with changes in our society, as it diversifies and becomes increasingly multifunctional. Here, we introduce curbstones developed together with Toyota T&S Construction Co., Ltd. to help eliminate utility poles.

-

- Image 1: Impression of future mobility infrastructure

Concept of Curbstones to Eliminate Utility Poles

In your future mobility infrastructure research and development, why did you focus on elimination of utility poles?

- Nakatani

- We began engaging in mobility infrastructure R&D, and when we investigated infrastructure industry trends and issues, we recognized that construction to eliminate utility poles is extremely time-consuming and very costly. Generally, because gas and water pipes are buried under sidewalks, to accommodate electric cables, we need to relocate the existing pipes. We therefore turned our attention to the curbstones that separate roadways and sidewalks, and wondered if it was possible to make them hollow to incorporate power and communications lines and thereby easily eliminate utility poles. (Reference: Elimination of Utility Poles by the Ministry of Land, Infrastructure, Transport and Tourism)

Incorporating electric cables into curbstones to eliminate utility poles is an interesting idea. Can you tell us about these curbstones?

- Nakatani

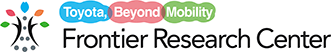

- The concept involves including a hollow cavity in curbstones, divided into upper and lower halves. It is a simple structure where the lower "duct" half, buried in the ground, houses the electric cables, and the top "curbstone-shaped lid" half is bolted on (Image 2). A key feature of this system is that gas and water pipes are generally not installed under curbstones, so they are not a concern when installing curbstones to eliminate utility poles (utility curbstones). Also, unlike conventional installation methods, there is no need for deep digging. In addition, because they are positioned away from buildings, there is little chance that installation would cause building collapse. As a result, installation work is less costly and takes less time. We therefore believe that it would have less impact on people's daily lives.

-

- Image 2: Concept of utility curbstones

It seems unusual for Toyota to develop a concrete product.

- Nakatani

- Actually, after witnessing the burnt plains following the war, Toyota's founder Kiichiro Toyoda wondered if it was possible to make concrete homes that wouldn't burn, and conducted in-house research into pre-cast concrete products. Later, he founded a company called Yutaka Precon (now Toyota T&S Construction Co., Ltd.), which helped with the production of concrete panels for mass-constructed public housing. Toyota T&S Construction inherited that technology and we conducted joint research with them, leveraging pre-cast concrete techniques, to realize the concept of utility curbstones.

Design Process

I've never seen curbstones like this. How did you design them?

- Nakatani

- There is no precedent for these curbstones that combine the functions of a curbstone and a common utility duct to house electric cables. Consequently, we had no design criteria or requirements. Thus, in addition to the requirements for conventional common utility ducts, we set a requirement that the curbstones prevent damage to internal electric cables even when vehicles pass over them.

How did you decide the design requirements?

- Nakatani

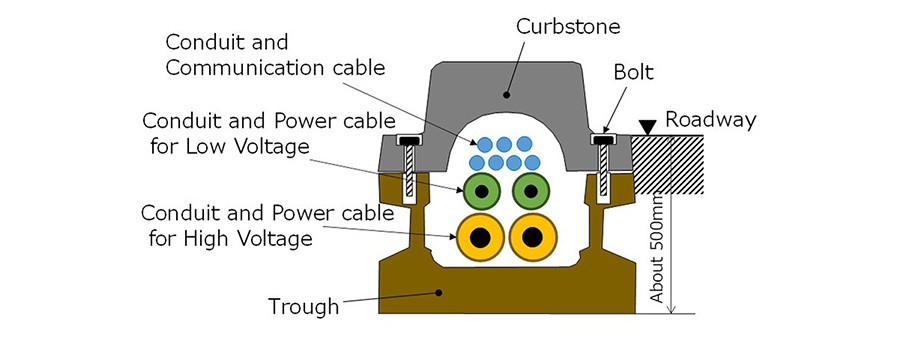

- First, we narrowed down to the three key situations that curbstones are regularly exposed to. The first is when a vehicle mounts slowly when parallel parking on the road shoulder. The second is when a vehicle mounts at high speed in the unlikely event of an accident. The third is repeated mounting, such as when entering or exiting a shop or residence. Also, we manufactured a load measuring device shaped like a curbstone fitted with multiple load cells that detect internal load, to investigate the load when a vehicle actually mounts the curbstones (Image 3).

-

- Image 3: Load measuring device

- Nakatani

- In regard to the three situations described above, the device measured the proportions of three directions of load: vertical, sideways and horizontal, as we tested using passenger vehicles and large trucks, mounting at various speeds and angles of entry. We adjusted the loads in the truck carry-tray according to its loading capacity. Of course, we were anxious of the cargo shifting the first time a truck mounted the load measuring device.

-

- Image 4: Test mounting (passenger vehicle)

-

- Image 5: Test mounting (large truck)

-

- Image 6: Preparing the measuring device

In what ways did you actually use the loads measured in the design of the curbstones?

- Nakatani

- First, Toyota T&S Construction used the load breakdowns in designing the exterior shape of the curbstones and the specifications for the reinforcing bars. Then, based on this, Toyota applied strength and impact simulation technology fostered through vehicle development in consideration of shape details.

Can you describe the simulations in detail?

- Nakatani

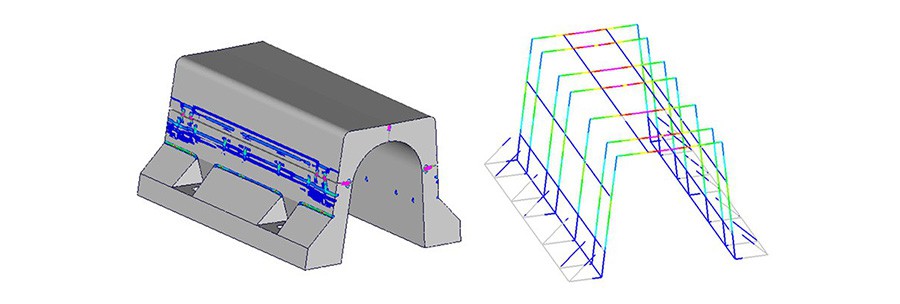

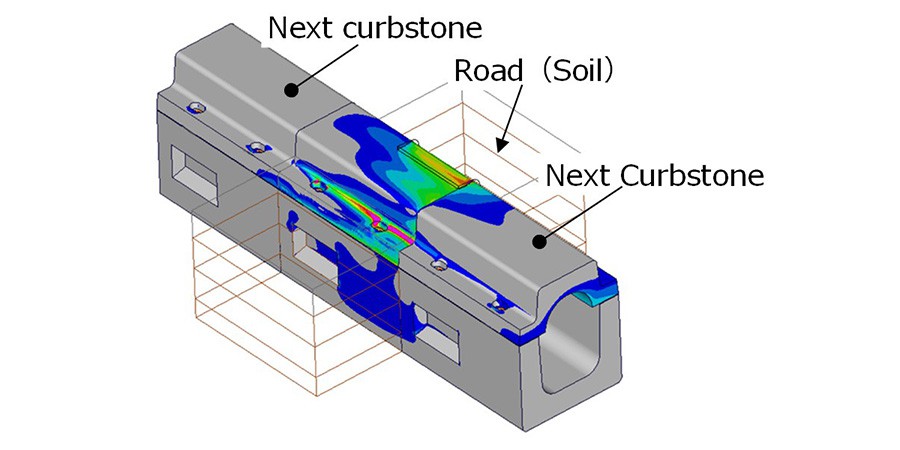

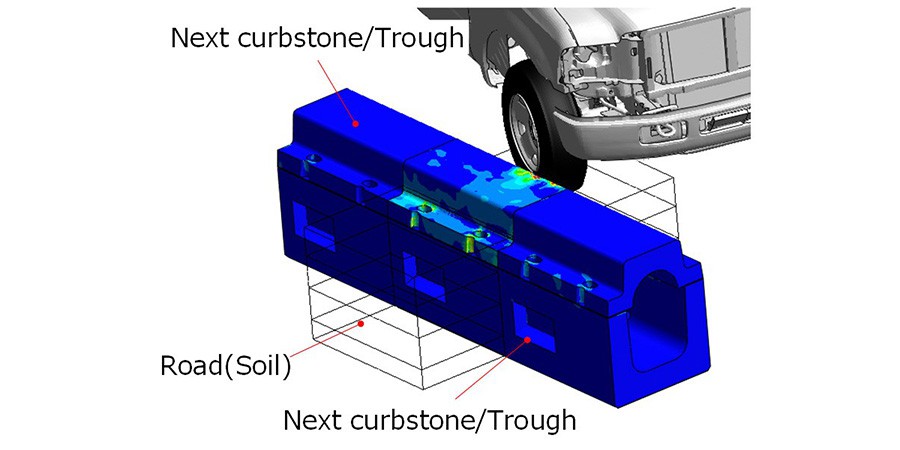

- We conducted simulations of curbstones set into the ground to check for cracking to the curbstones, deformity of the reinforcing bars, and so on when mounted by a vehicle. Initially, we created a stand-alone model of the curbstones that accurately simulated the shape, physical properties of the concrete, and the internal reinforcing bars, then confirming that generally the same behavior was shown in the stand-alone strength tests as in the simulations. Next, we used stand-alone models to construct a model for analyzing road installation that incorporated the physical properties of roads and adjacent curbstones. We added the loads derived in previous tests, and monitored deformity, stress, and so on of the curbstones, repeatedly revising the external shape, positioning of the reinforcing bars, and other aspects to ascertain the optimum specifications. Lastly, using the final shape of the curbstones, we conducted simulations of mounting a model vehicle to ensure there were no strength-related issues.

-

- Image 7: Results of strength test simulations using the stand-alone curbstone model (left: concrete stress distribution; right: load distribution on reinforcing bars)

-

- Image 8: Stress distribution in the model for analyzing road installation

-

- Image 9: Results of vehicle mounting simulations

Future Prospects

It seems that there will be no issues to incorporate curbstones developed in this research into existing roads. What are your thoughts on future prospects?

- Nakatani

- In this stage of research, we were able to develop a method for eliminating utility poles, through new infrastructure design to support future mobility, fusing Toyota's simulation technologies with Toyota T&S Construction's pre-cast concrete technologies. Going forward, Toyota hopes to continue to promote research and development into new infrastructure systems, with the aim of realizing a safe and secure society integrating people, mobility and infrastructure, and a society that is environmentally friendly and comfortable.

-

- Image 10: Development team members: (Clockwise from top-left) Ito, Kojima and Kato (Toyota T&S Construction), Masuki, Yasui, Nakatani (author), Takeuchi and Fujiwara (Toyota Motor Corporation Frontier Research Center)

Message from Representative of Toyota T&S Construction

Our company began with building fireproof housing, and has since engaged in construction and civil works using pre-cast concrete. Most recently, we have been involved in the manufacture of prestressed floor slabs regarding bridge replacement work, which are essential for cars. The challenge in development of curbstones to replace utility poles was to find an extremely simple way to incorporate a new mechanism for power supply into existing roads without reducing road width. To achieve this, we turned our attention to curbstones at the edge of roads. In order to realize this new concept, we conducted experiments that anticipated the risks and repeated construction verification to establish a design method, in collaboration with members of the Frontier Research Center. It was a challenging issue, but I am thankful to have been able to jointly participate in developing this proposal for a new concept of mobility infrastructure.

Author

Hiroyuki Nakatani, Project Manager, Toyota Motor Corporation R-Frontier Div. Innovative Infrastructure Design Group

He is involved in planning and development of new infrastructure systems that support present and future mobility.

For this project, he collaborated with internal and external members, and helped drive development.

Contact Information (about this article)

- Frontier Research Center

- xr-probot@mail.toyota.co.jp