Jun. 07, 2019

3) Battery development and supply

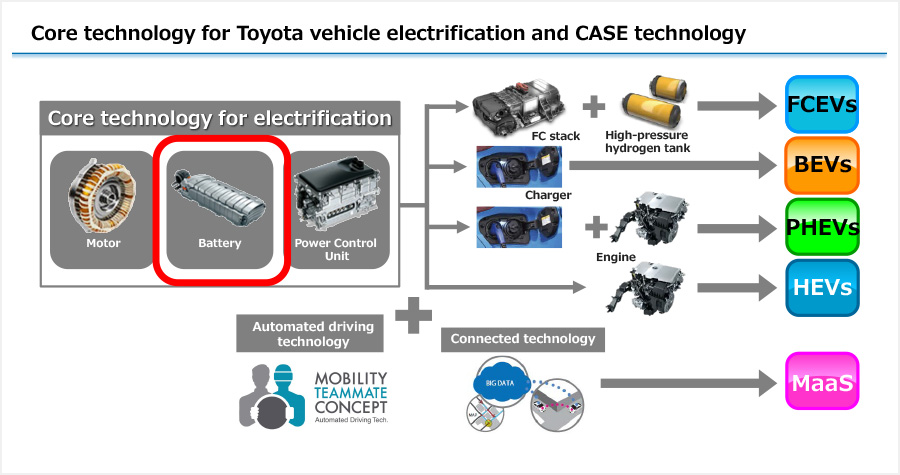

Batteries represent a core technology that is common to all electrified vehicles, and they play a key role in determining BEV performance.

Toyota will naturally apply to BEVs the technologies that it has cultivated in the process of achieving cumulative sales of 13 million units of hybrid vehicles.

Here is an example of how such technologies are being applied.

This graph plots battery capacity and fuel efficiency in terms of vehicle weight, for HEVs.

It illustrates the advantages of the effectiveness of Toyota's electrification systems.

In general, the higher the capacity of a battery, the more energy the battery can store, which is advantageous in improving the fuel efficiency of an HEV.

However, the larger the battery, the heavier it becomes, and more space is needed to install it.

Additionally, it becomes more expensive.

While the capacity of batteries used in Toyota's HEV system is smaller than that of batteries used in the systems of other manufacturers, system efficiencies result in good fuel efficiency.

Efficient power input and output among the battery, PCU, and electric motor or motors in Toyota's system is the result of technologies that Toyota will apply to the making of highly efficient BEVs.

Toyota has also applied these technologies to its PHEVs.

This graph compares the electric-powered cruising ranges per battery capacity of the Prius PHEV and of the PHEV of another manufacturer.

The Prius PHEV achieves a longer electric-powered cruising range than that of the other PHEV.

The technologies that Toyota has accumulated in its development of HEVs have been successfully applied to improving the electric-powered driving performance of Toyota's PHEVs.

Toyota believes that this makes it evident that such technologies can also be applied to BEVs.

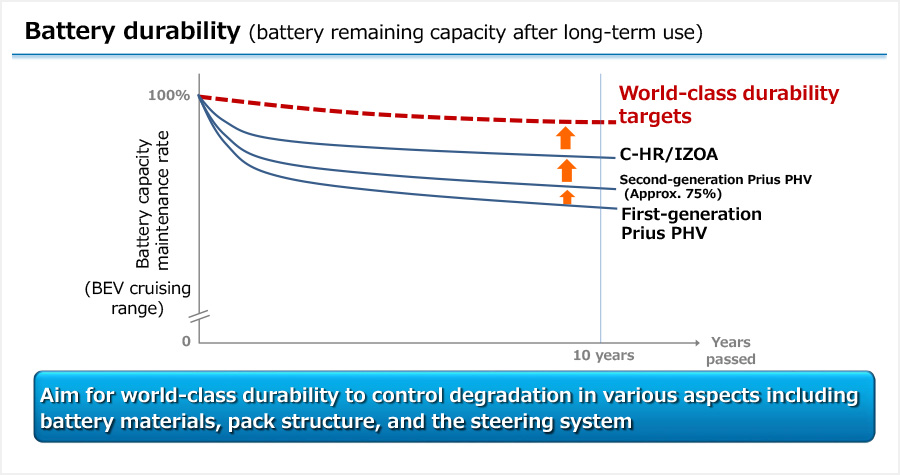

Now let us turn to an explanation of battery durability, or, in other words, battery residual capacity after long use, which can largely affect BEV performance.

Both the first-generation Prius PHEV released in 2012 and the second-generation Prius PHEV released in 2017 achieved battery durability that was among the best at the times of their releases.

That was the result of an accumulation of technologies for restraining battery degradation from various angles, such as in the choice of battery materials, in the design of battery-pack construction, and in control systems.

Toyota is aiming for even a higher level of durability for the BEV C-HR to be introduced in 2020, and it is continuing to advance development to achieve the world's highest level of durability performance for when it is time to commercialize a Toyota BEV for global rollout.

Toyota believes that improving battery durability is directly linked to offering highly environment-friendly and attractive BEVs.

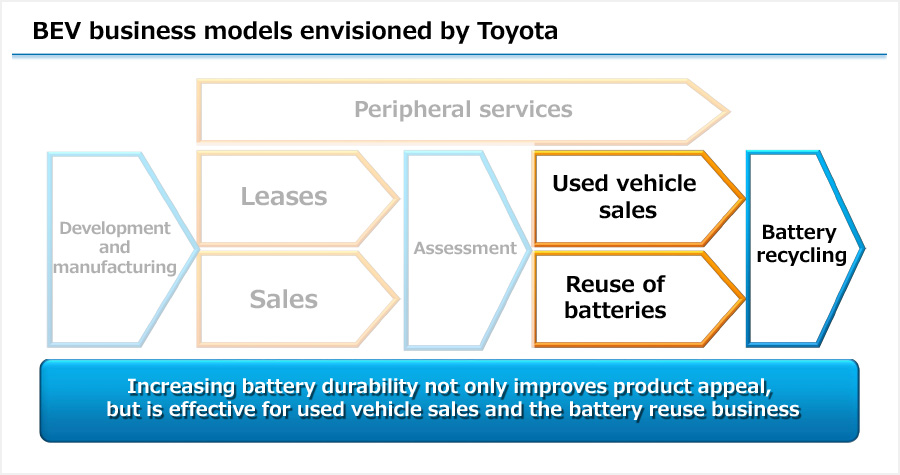

In the new business model that Toyota is constructing for BEVs, Toyota aims to promote sales of previously owned BEVs and to promote new businesses related to the reuse of batteries.

Toyota views battery durability as becoming more and more important.

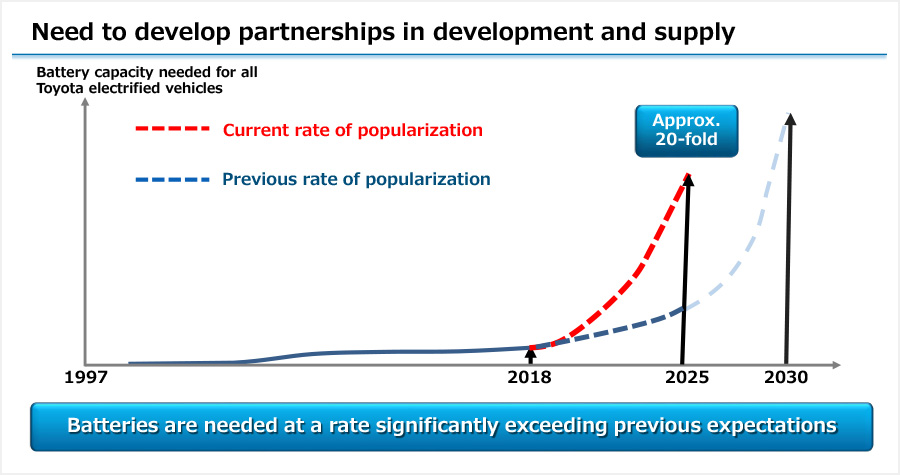

Taking a look next at battery supply, the growth of electrified vehicles has gone beyond Toyota's original expectations, and, more than in the case of HEVs and PHEVs, BEVs require large-capacity batteries.

There is a need to prepare many batteries within a short time.

From the aspects of both development and supply, Toyota intends to promote the building of a new structure.

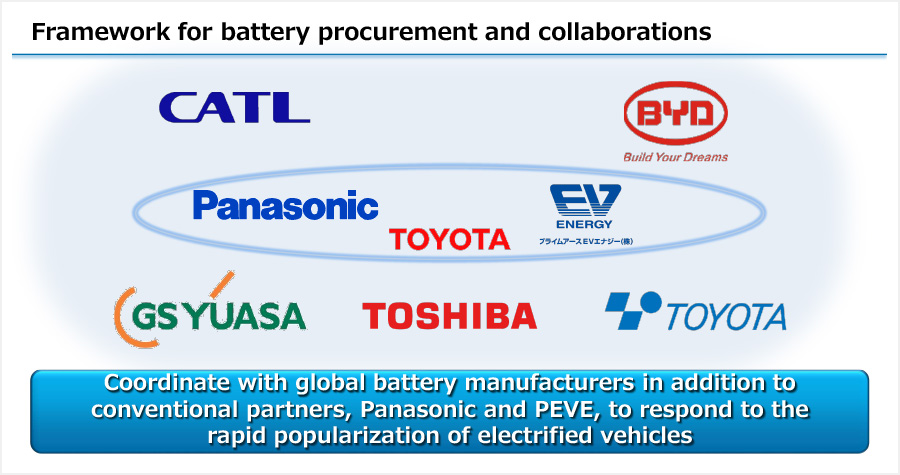

To date, Primearth EV Energy has been established as a Toyota battery partner, and Toyota is now readying a new company jointly with Panasonic.

Amid the rapid expansion of electrified vehicles, there is a need for Toyota to promptly respond to various regional needs.

For this, Toyota will create a battery procurement system capable of making BEV popularization a reality by cooperating and coordinating with battery manufacturers around the world that share its development vision, namely CALT, BYD, GS Yuasa, Toshiba, and Toyota Industries.